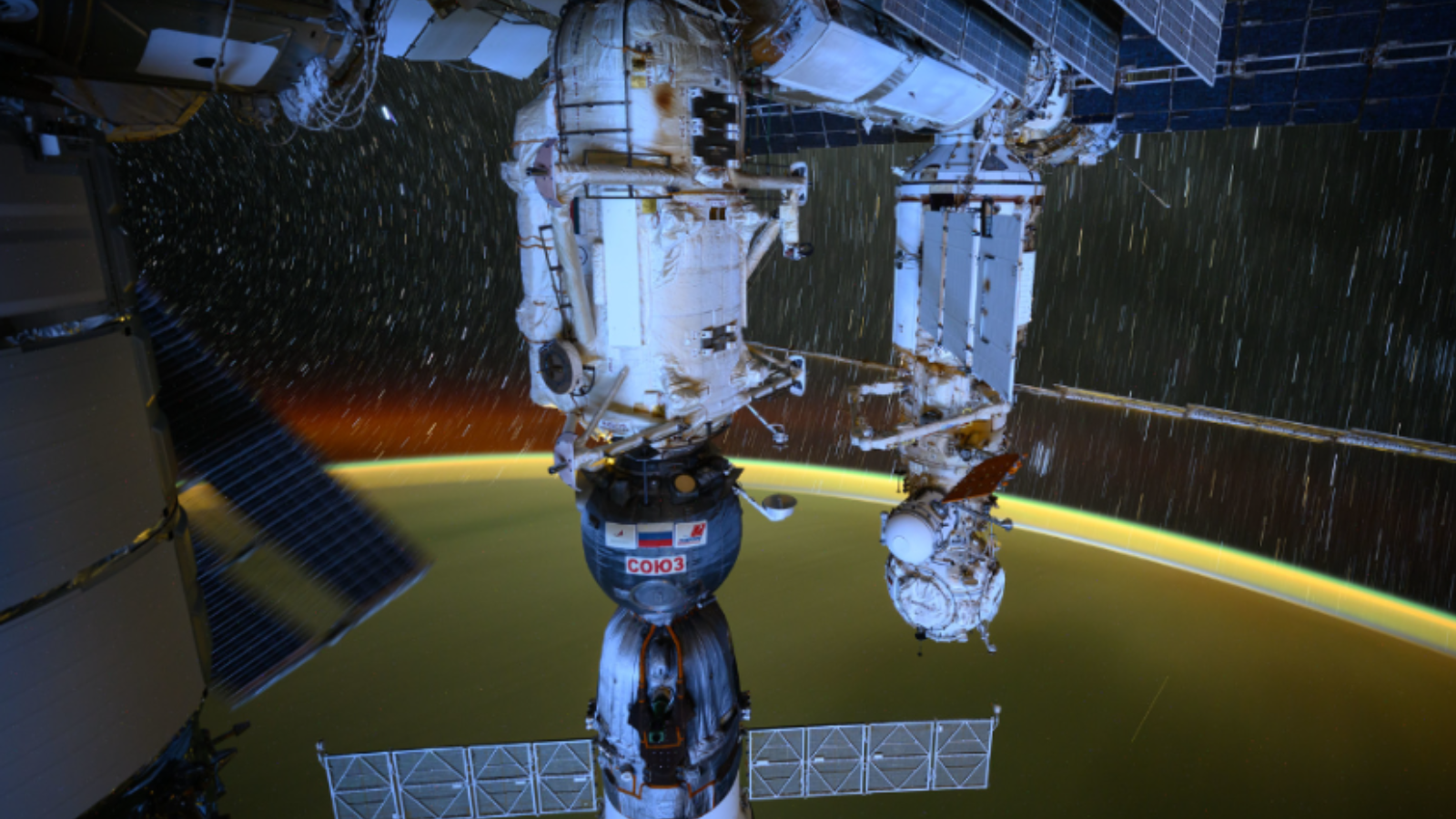

A 3D printer has passed its final set of NASA checks, clearing the way for the device to launch toward the International Space Station in August.

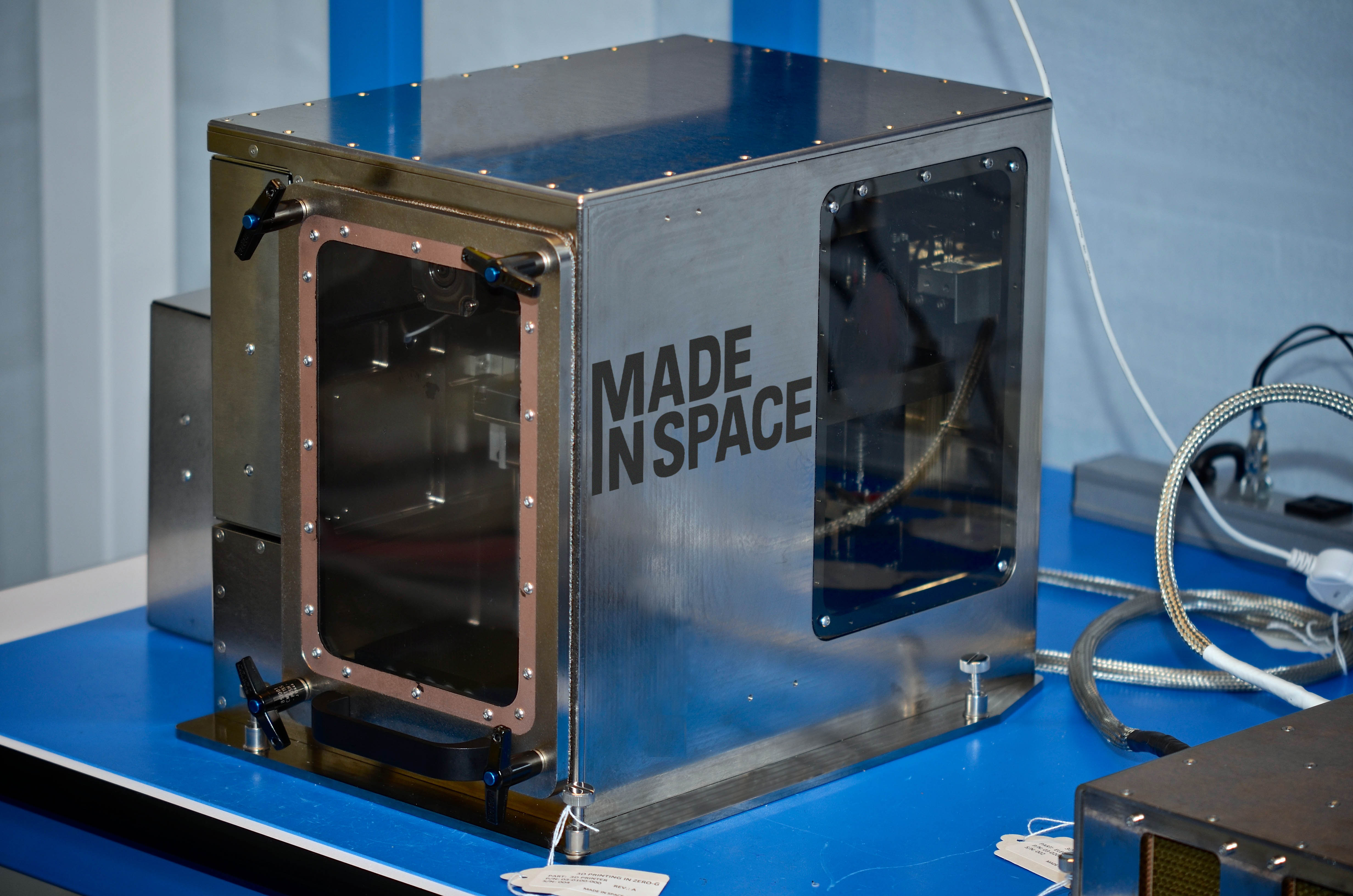

A series of trials at the agency's Marshall Space Flight Center in Alabama has verified that the 3D printer — developed by California-based startup Made in Space in cooperation with NASA, as part of a project known as 3D Print — meets all the requirements for use aboard the orbiting lab, officials announced today (June 12).

"NASA was able to provide key guidance on how to best comply with strenuous space certification, safety and operational requirements, and Made In Space excelled at incorporating that insight into the design," Niki Werkheiser, the NASA 3D Print project manager, said in a statement. [3D Printing in Space: A New Dimension (Photo Gallery)]

"As a result, the hardware passed testing with flying colors," Werkheiser added. "Made In Space now has first-hand experience of the full 'A-to-Z' process for designing, building and testing hardware for spaceflight."

The printer is now cleared for takeoff aboard the next cargo mission the private company SpaceX will fly to the space station for NASA using its robotic Dragon capsule and Falcon 9 rocket. That flight is expected to launch in August, though a final date has not been set.

The testers at Marshall looked at a number of factors, from the 3D printer's ability to withstand the rigors of launch to its compatibility with space station interfaces, NASA officials said. Engineers also tested a set of objects printed by the device on Earth, which will serve as ground controls. (The same items will also be printed aboard the orbiting lab.)

3D printers use a technique called extrusion additive manufactuing to build objects layer by layer out of polymers, metals and other raw materials. The technology could help make space exploration cheaper and more efficient, advocates say, by reducing the need to launch all mission components and parts from Earth.

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

"The ability to manufacture on demand in space is going to be a paradigm shift for the way development, research and exploration happen in space," said Michael Snyder, lead engineer and director of R&D for Made In Space.

Once the machine is installed in the space station's Microgravity Science Glovebox (MSG), it will print out a set of 21 test parts and tools, which will eventually be returned to Earth for analysis.

While these initial activities aim to verify the additive-manufacturing process in microgravity, the 3D Print project also intends to go a step further, demonstrating the usability of some parts, officials said. And when the experiment is over, Made in Space plans to install a permanent 3D printer aboard the International Space Station.

"Passing the final tests and shipping the hardware are significant milestones, but they ultimately lead to an even more meaningful one — the capability for anyone on Earth to have the option of printing objects on the ISS," said Made In Space CEO Aaron Kemmer. "This is unprecedented access to space."

Follow Mike Wall on Twitter @michaeldwall and Google+. Follow us @Spacedotcom, Facebook or Google+. Originally published on Space.com.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Michael Wall is a Senior Space Writer with Space.com and joined the team in 2010. He primarily covers exoplanets, spaceflight and military space, but has been known to dabble in the space art beat. His book about the search for alien life, "Out There," was published on Nov. 13, 2018. Before becoming a science writer, Michael worked as a herpetologist and wildlife biologist. He has a Ph.D. in evolutionary biology from the University of Sydney, Australia, a bachelor's degree from the University of Arizona, and a graduate certificate in science writing from the University of California, Santa Cruz. To find out what his latest project is, you can follow Michael on Twitter.