MOFFETT FIELD, Calif. — Why build space station parts in factories here on Earth when they're ultimately going to end up in space? And why use a factory at all when you can just crank those parts out with a 3-D printer?

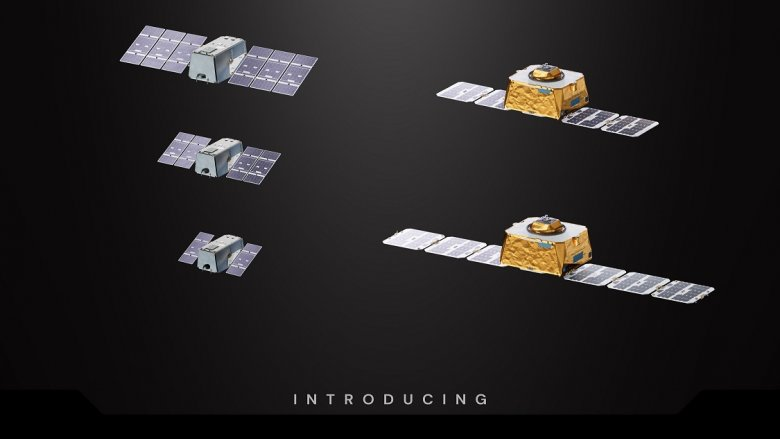

A new company called Made In Space is posing these questions to the aerospace industry — as well as to potential investors. Made in Space wants to launch 3-D printers into orbit and use them to make parts for spacecraft and space stations, which would be assembled in zero gravity.

Three-dimensional printers make objects by sequentially depositing thin layers of "feedstock," which can be metal, plastic or a variety of other materials.

Printing out parts in space would save a great deal of time and money, according to Made in Space. And the technology could eventually be transplanted to other worlds such as the moon, where it could help human colonies gain a foothold by printing out robot parts or buildings, piece by piece.

"It makes perfect sense that we should build everything for space, in space," said Jason Dunn, one of Made in Space's founders.

Dunn discussed the company's business model and plans here recently at NASA's Ames Research Center, during a conference called Space Manufacturing 14: Critical Technologies for Space Settlement. The meeting was organized by the nonprofit Space Studies Institute.

Saving time and money

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Made in Space took shape this past summer, when its founders attended Singularity University here at Ames.

Singularity University, co-founded in 2008 by futurist and inventor Ray Kurzweil, is a 10-week program that brings leaders in various fields together with talented young people, many of them graduate students. The goal is to develop technologies to address some of humanity's biggest problems.

Dunn and Made in Space's other founders think space-based 3-D printing could have a big impact, enabling easier and cheaper access to space. The technology has advanced greatly in the past several years, with one company now selling a home-use desktop printer for less than $1,000.

"These things are not just prototypes anymore," Dunn said.

Printing out components in space could reduce structures' mass by 30 percent or so, Dunn said, because engineers wouldn't have to build the parts to withstand the rigors of launch, which include high g-forces and lots of vibration.

Instead, they'd just launch the feedstock, which Dunn described as a "gray goo" that could fit into almost any nook and cranny on a rocket. When it comes to launch, the heavier a payload is, the more fuel is needed to lift it off, so such a significant slim-down would save a lot of money.

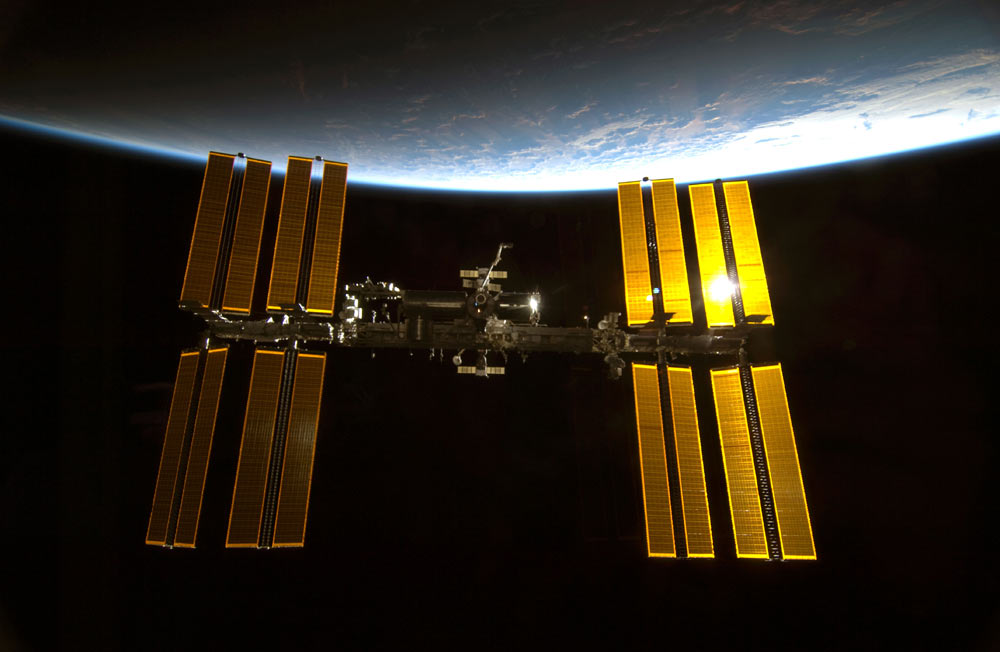

Space printing could also reduce any time delays caused by broken or malfunctioning equipment, Dunn said. Rather than shuttling a replacement part from Earth to a space station, 3-D printers aboard the station could simply crank out whatever's needed. And the broken part could be recycled into feedstock.

Missions to other worlds, such as the moon or Mars, could take 3-D printers along to help establish human settlements, according to Dunn. Using metal and plastic as feedstocks, they could print out robot parts. Using Mars or moon dirt, they could build up dwellings, piece by piece.

Some researchers have used 3-D printers to make items out of concrete, so lunar regolith — a form of moon soil — should work well as a feedstock, said Adam Ellsworth, a scientific adviser with Made in Space.

Theoretically, metallic feedstocks could one day be sourced on these extraterrestrial worlds too, minimizing the need to haul materials all the way from Earth.

"You can just bring the files of the tools, and the files of the parts," Dunn said.

Early days yet

The company is thinking big, but it's only just starting out. Made in Space has been assessing different 3-D printer models, and it's already printed out some space-grade plastic parts, according to Ellsworth.

The next big step will be to see how various printers perform in a weightless environment. Made in Space hopes to do this within the next six months, Dunn said.

For its initial tests, the company may rely on suborbital vehicles under development by private spaceflight companies, some of which could provide about 20 minutes of weightlessness per flight, Dunn said. It takes hours to print a full part, but printing out pieces on a suborbital flight could be a good first step, according to Dunn.

If a printer passes this test, the next phase may be a full trial in orbit, perhaps aboard the International Space Station.

Three-dimensional printers have already shown an ability to make small, complex products, even some with moving parts. But the company wants to show that they can build large structures, too, Dunn said. So an in-space trial might involve printing out long beams that could help construct a space station.

Even though the company is still very young, both the public and private sector are intrigued, according to Dunn.

"There's definitely a lot of interest in what we're trying to do," he said.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Michael Wall is a Senior Space Writer with Space.com and joined the team in 2010. He primarily covers exoplanets, spaceflight and military space, but has been known to dabble in the space art beat. His book about the search for alien life, "Out There," was published on Nov. 13, 2018. Before becoming a science writer, Michael worked as a herpetologist and wildlife biologist. He has a Ph.D. in evolutionary biology from the University of Sydney, Australia, a bachelor's degree from the University of Arizona, and a graduate certificate in science writing from the University of California, Santa Cruz. To find out what his latest project is, you can follow Michael on Twitter.