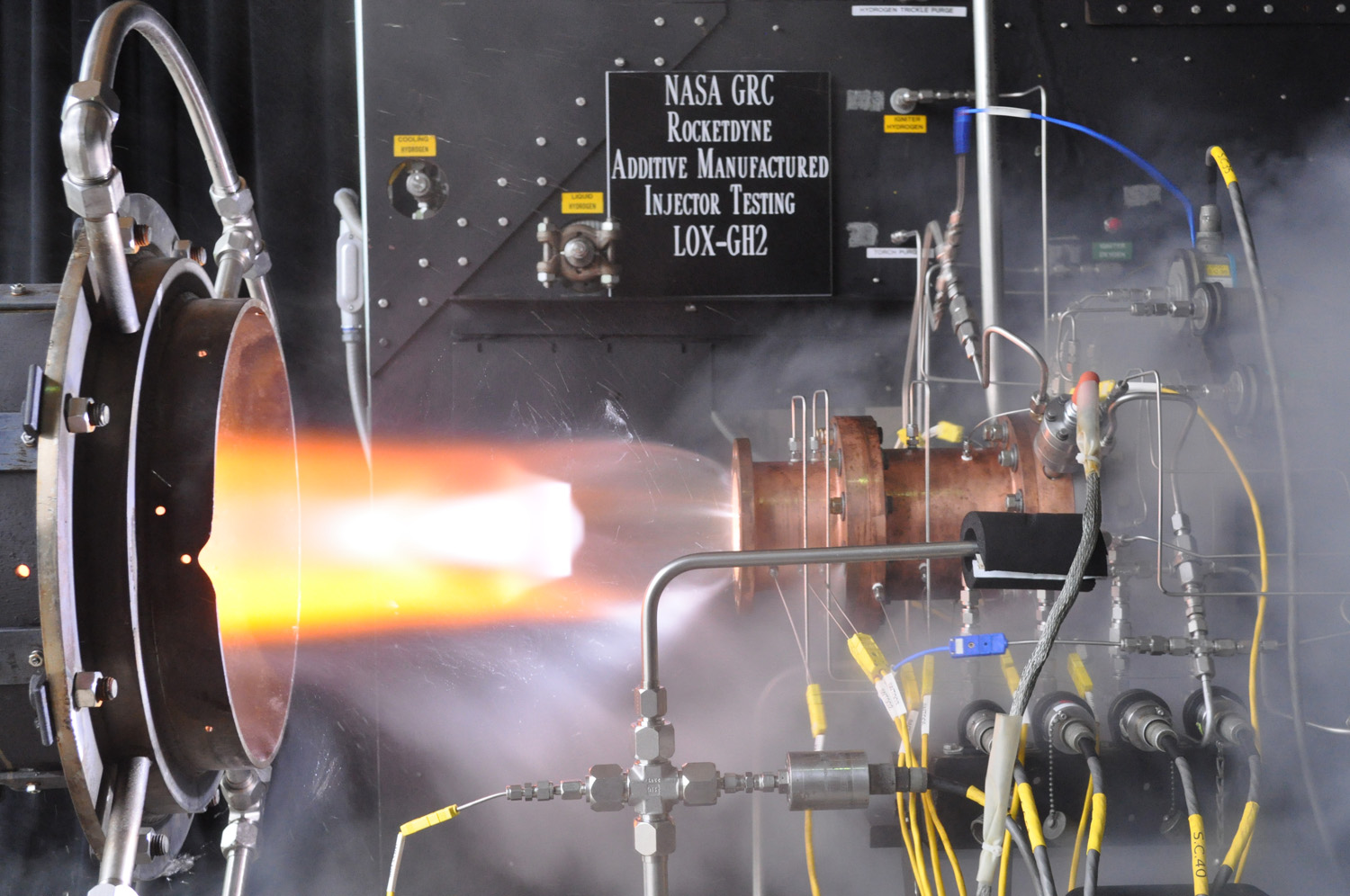

3D-Printed Rocket Engine Part Passes Key NASA Test

A 3D-printed rocket engine injector has passed a major NASA test, potentially heralding a new age of propulsion-system manufacturing, space agency officials say.

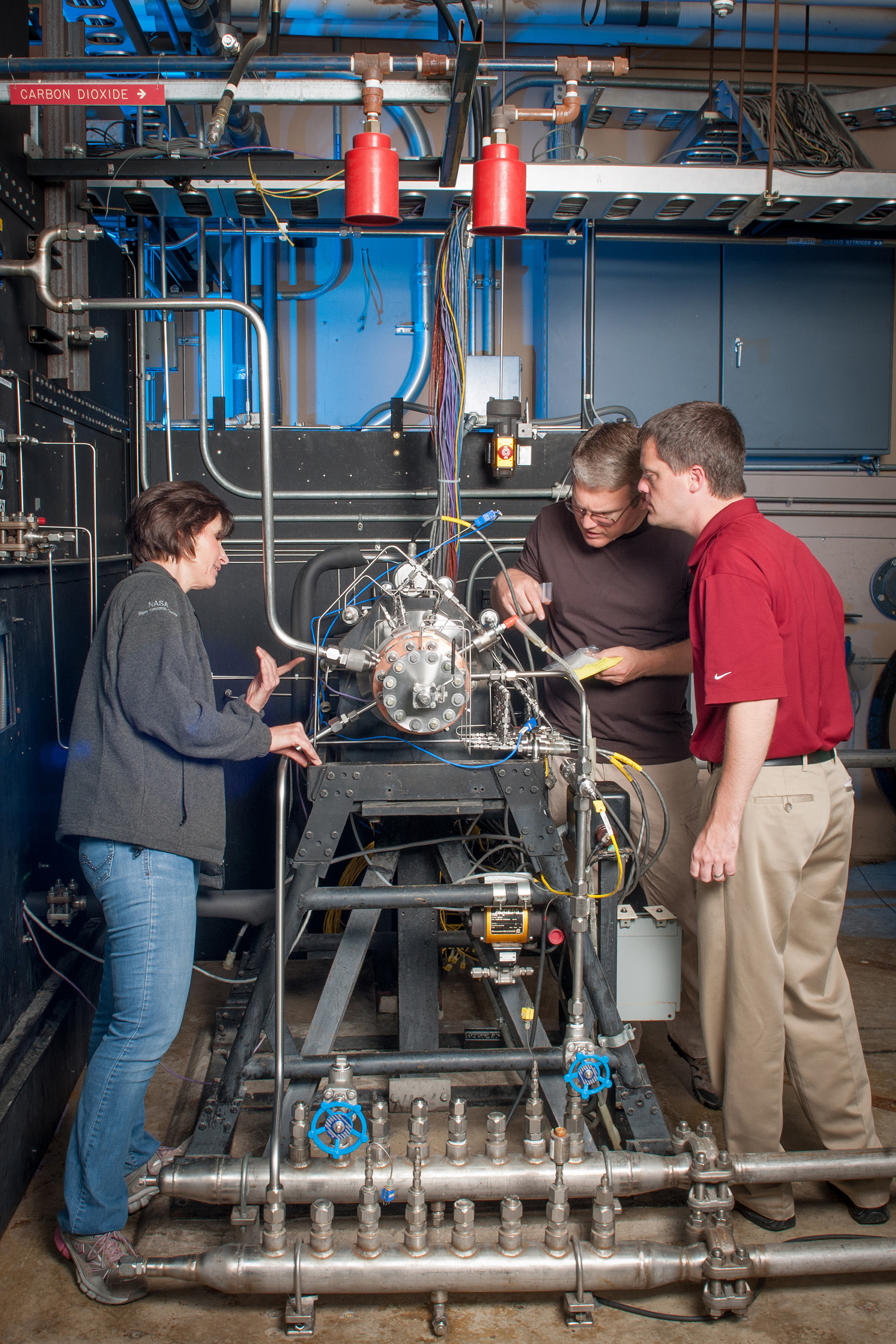

NASA and Florida-based company Aerojet Rocketdyne put the injector — which was built using 3D printing (also called "additive manufacturing") technology — through a series of hot-fire trials, agency officials announced last week.

"Hot-fire-testing the injector as part of a rocket engine is a significant accomplishment in maturing additive manufacturing for use in rocket engines," Carol Tolbert, manager of the Manufacturing Innovation Project at NASA's Glenn Research Center in Cleveland, Ohio, where the tests were conducted, said in a statement. [10 Amazing 3D-Printed Objects]

"These successful tests let us know that we are ready to move on to demonstrate the feasibility of developing full-size, additively manufactured parts," Tolbert added.

Aerojet Rocketdyne crafted the engine injector using high-powered lasers that liquefied and fused metallic powders into the proper structure.

Rocket engine injectors typically take a year or more to build. Employing 3D printing technology can reduce this to less than four months while also cutting costs by 70 percent, NASA officials said.

"NASA recognizes that on Earth and potentially in space, additive manufacturing can be game-changing for new mission opportunities, significantly reducing production time and cost by 'printing' tools, engine parts or even entire spacecraft," Michael Gazarik, NASA's associate administrator for space technology in Washington, D.C., said in a statement.

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

"3D manufacturing offers opportunities to optimize the fit, form and delivery systems of materials that will enable our space missions while directly benefiting American businesses here on Earth," he added.

NASA's interest in 3D printing appears to be strong and growing. For example, the space agency is partnering with California company Made in Space to send a 3D printer to the International Space Station next year.

And NASA recently funded the development of a prototype "3D pizza printer" that could help feed astronauts on long space journeys, such as the 500-day trek to Mars.

3D printing has been used to craft certain rocket parts before, but usually this form of manufacturing is employed to build less critical components of the complex machines, Aerojet Rocketdyne additive manufacturing program manager Jeff Haynes said.

"The injector is the heart of a rocket engine and represents a large portion of the resulting cost of these systems," Haynes said in a statement. "Today, we have the results of a fully additive manufactured rocket injector with a demonstration in a relevant environment."

Follow Miriam Kramer @mirikramer and Google+. Follow us @Spacedotcom, Facebook and Google+. Original article on SPACE.com.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Miriam Kramer joined Space.com as a Staff Writer in December 2012. Since then, she has floated in weightlessness on a zero-gravity flight, felt the pull of 4-Gs in a trainer aircraft and watched rockets soar into space from Florida and Virginia. She also served as Space.com's lead space entertainment reporter, and enjoys all aspects of space news, astronomy and commercial spaceflight. Miriam has also presented space stories during live interviews with Fox News and other TV and radio outlets. She originally hails from Knoxville, Tennessee where she and her family would take trips to dark spots on the outskirts of town to watch meteor showers every year. She loves to travel and one day hopes to see the northern lights in person. Miriam is currently a space reporter with Axios, writing the Axios Space newsletter. You can follow Miriam on Twitter.