Weaving for Mars: Ancient Technique Will Aid Red Planet Mission

A family-owned weaving business in Pennsylvania that started out making silk hat bands in the 1920s is helping NASA build key components for the Orion spacecraft, which could help carry humans to Mars and other deep-space destinations.

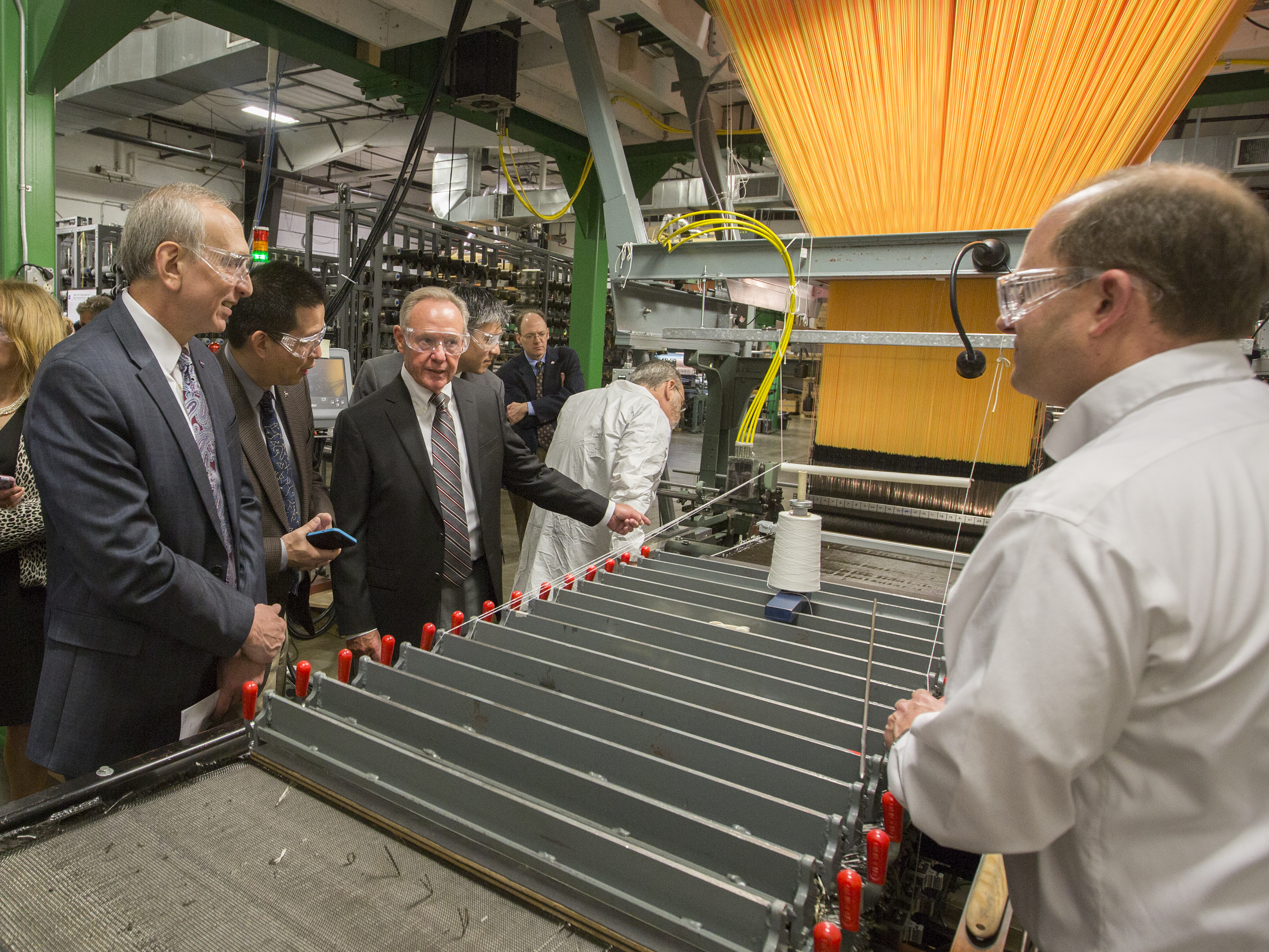

Bally Ribbon Mills was founded in 1923 in Bally, Pennsylvania, and is still run by members of the family that started the business, according to an article published by NASA. Today, the company still uses classic weaving techniques, but with more advanced materials, including carbon fiber and quartz, and with more advanced applications, like building parts for Formula One race cars.

Now, the company is helping NASA build an improved heat shield for the agency's Orion human spacecraft. By weaving together threads made of a quartz composite, the company can produce a 3-inch-thick (7.6 centimeters) material using a weaving method that dates back millennia, according to an article in NASA Spinoff, a publication about nonspace applications that come out of the agency. [Photos: NASA's Space Launch System for Deep Space Flights]

Taking the heat

When Orion returns to Earth from space, the craft will fall through Earth's atmosphere, where friction with air particles will generate an incredible amount of heat. Most of Orion's heat shield consists of "a low-density material that's very good at insulating" the inside of the craft, said Jay Feldman, technical lead on the heat shield project with Bally at NASA's Ames Research Center.

But the insulating material isn't very strong, Feldman said. At various points across the heat shield, including where it connects the crew capsule to the service module (which carries supplies including oxygen and fuel), NASA engineers needed a much stronger material that could also serve as an insulate. These connection regions use something called compression pads, according to the article, which had previously been made of steel and carbon-fiber composite. But during Orion's first test flight, in 2014, the pads conducted a lot of heat, more than would have been safe for a crewed flight.

Now, Orion's compression pads will consist of a 3D material made from fibers consisting partly of quartz. This group of compression pads is known as the 3D Multifunctional Ablative Thermal Protection System (3D-MAT).

The 3D-MAT material is considered "three-dimensional" because it has the "same number of fibers going in all three directions," the article said. Three threads, all pointing in perpendicular directions, are woven together. The material is then sent to another company that infuses the sheets of material with resin for curing and to fill pores left by the weaving. Then, the sheets are honed into the final shape.

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

When it's complete, the final product is 3 inches thick and "like a brick," Curt Wilkinson, a senior textile engineer at Bally Ribbon Mills, said in the article. "We are packing a lot of fiber in there. Many times during the development, we were unsure if we could actually pack the fiber volume that [NASA was] looking for."

The material has the combination of factors that NASA needs for the heat shield compression pads.

"The material can be a structure, it can be a thermal-protection system, it can be a shock absorber, and it can carry loads," Ethiraj Venkatapathy, a project manager and chief technologist for the Entry Systems & Technologies Division at NASA, said in the article.

Future tech

The engineers at NASA and Bally Ribbon Mills are looking into using the 3D-MAT material in other areas of the heat shield, and its applications could even extend beyond the agency, the article said. Government agencies, including the Department of Defense, and aerospace companies "have expressed interest" in thermal-protection systems made with the 3D-MAT material, according to the article. Even the company's clients in the Formula One world are interested in the material because of its increased thickness compared to other woven structural material.

Researchers at NASA Ames were already working with engineers at Bally Ribbon Mills to develop a potential next-generation heat-shielding material that included the 3D quartz-fiber composite. Weaving together fibers using machines may appear high tech, but the process still uses the same basic weaving technology the company employed in the 1920s, called a shuttle loom, the article said. This type of weaving loom has been used for "millennia," according to the article. The technique used to make the heat shield components is called 3D orthogonal weaving.

"We incorporate modern electronic components, and we also build and incorporate our own take-up systems, but the loom itself is extremely old," Wilkinson said in the article. "Using the same age-old steps of weaving, we're now weaving material that's going to go to Mars."

Follow Calla Cofield @callacofield. Follow us @Spacedotcom, Facebook and Google+. Original article on Space.com.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Calla Cofield joined Space.com's crew in October 2014. She enjoys writing about black holes, exploding stars, ripples in space-time, science in comic books, and all the mysteries of the cosmos. Prior to joining Space.com Calla worked as a freelance writer, with her work appearing in APS News, Symmetry magazine, Scientific American, Nature News, Physics World, and others. From 2010 to 2014 she was a producer for The Physics Central Podcast. Previously, Calla worked at the American Museum of Natural History in New York City (hands down the best office building ever) and SLAC National Accelerator Laboratory in California. Calla studied physics at the University of Massachusetts, Amherst and is originally from Sandy, Utah. In 2018, Calla left Space.com to join NASA's Jet Propulsion Laboratory media team where she oversees astronomy, physics, exoplanets and the Cold Atom Lab mission. She has been underground at three of the largest particle accelerators in the world and would really like to know what the heck dark matter is. Contact Calla via: E-Mail – Twitter