Blowing up: Inflatable space habitats could be key to exploring the solar system

It's high time to crank up the volume in space! That's the shout from several private firms that want to see an inflation factor for the future.

What is now being evaluated and tested is the use of "softgoods" to fashion inflatable/expandable airlocks and off-Earth habitats, not only for low Earth orbit, but also to provide comfy housing for future moon and Mars explorers.

First, however, there's a memory lane trip about this idea worth taking, one that also underscores how far things have evolved.

The roots of inflatable space tech

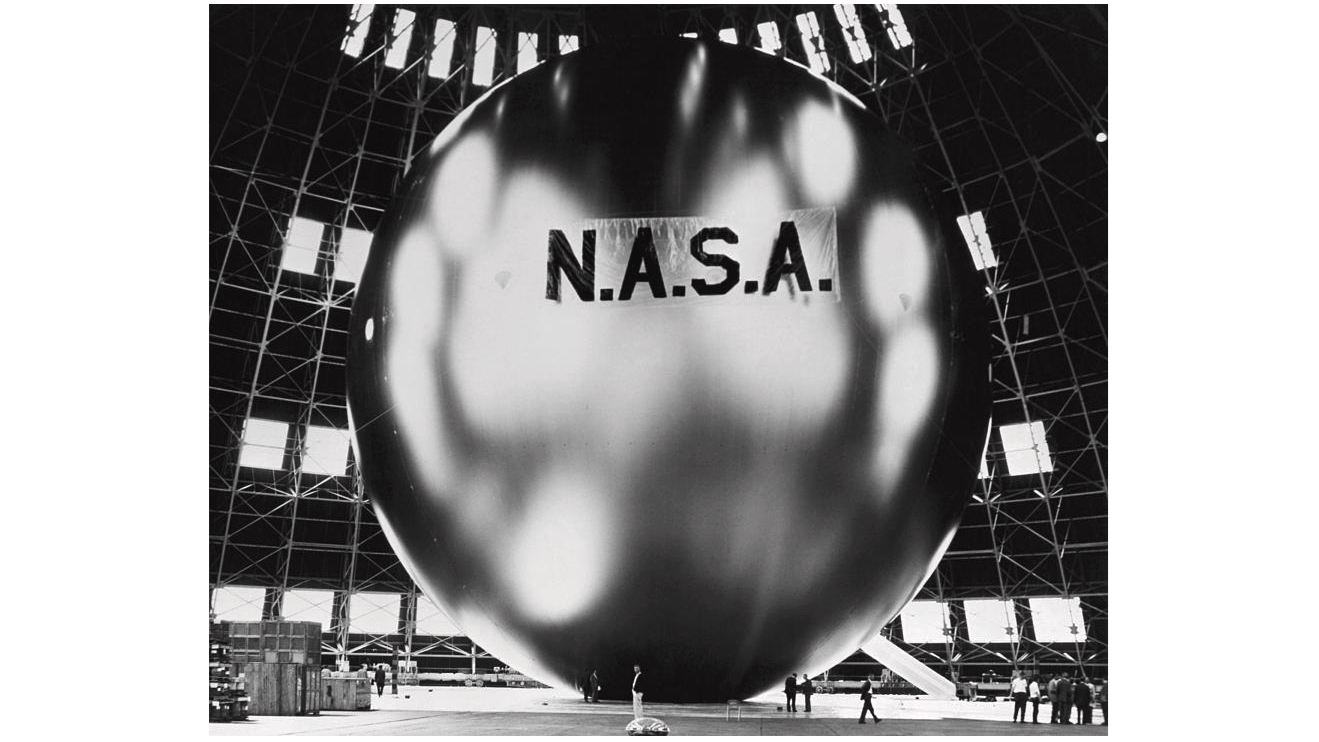

Take for example, Project Echo, which involved two American spacecraft, the first launched in 1960 and the second in 1964. They were thin-skinned Mylar balloon satellites. These gassed-up balloons — Echo 1 expanded to 100 feet (30.48 meters), while Echo 2 inflated to 135 feet (41 m) — tested the reflection of microwave signals from one point to another on Earth.

Related: Could these big expandable habitats help humanity settle the moon and Mars?

Then, in March 1965, Soviet cosmonaut Alexei Leonov made use of an inflatable airlock attached to his Voskhod 2 spacecraft to carry out humanity's first spacewalk. But that milestone turned out to be no stroll in the park.

The tethered Soviet spacewalker's suit stiffened so much in the vacuum of space, Lenov had to bleed off some of his suit's pressure, allowing him to finally bend the spacesuit joints to clamor back into his mothership.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Bigelow birthright

Enter the 21st century and the pioneering work of Robert Bigelow and his team at Las Vegas-based Bigelow Aerospace.

The company built two uncrewed free-flying expandable prototype modules that launched to Earth orbit in 2006 and 2007, respectively, under its Genesis program. They are still circling the globe to this day.

While drawing from NASA's canceled TransHab effort, the Bigelow Aerospace enterprise was a creative hub that furthered expandable space module technology.

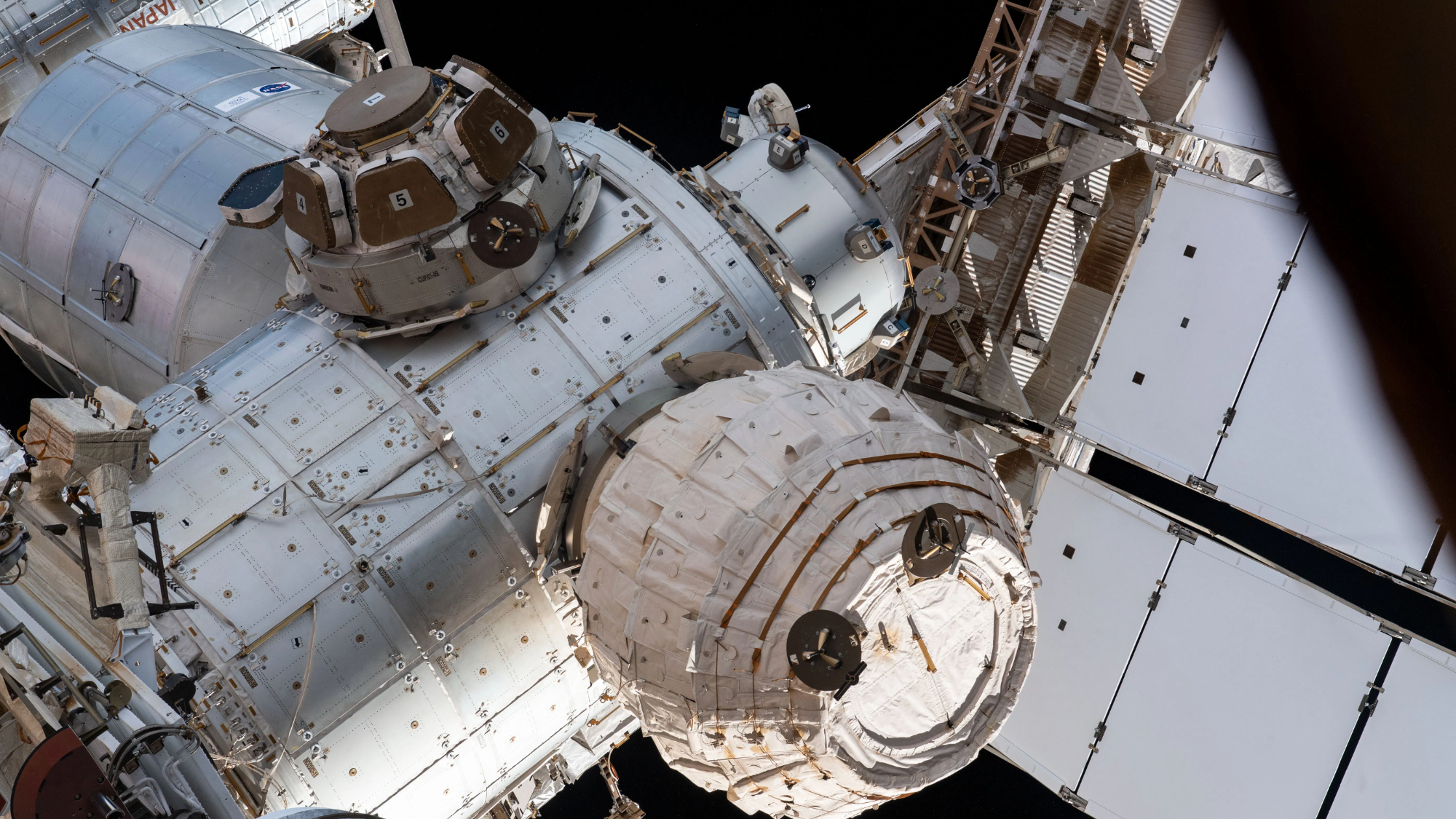

An outgrowth of their labor is now attached to the International Space Station (ISS). The Bigelow Expandable Activity Module, or BEAM for short, arrived at the ISS and remains attached to its Tranquility module to this day.

Bigelow Aerospace and its ground-breaking work in expandable modules included use of proprietary extensions of Vectran shield fabric, a stronger alternative to Kevlar. Vectran is a high-performance liquid crystal polymer fiber offering superior attributes compared to Kevlar.

Bigelow is no longer operating — the company closed its doors in 2020 — but its influence may still be felt going forward.

Expanding competition

Today, several leading firms are pushing forward on expandable structures in space, such as the new startup Max Space, which is working on inflatable habitats for Earth orbit, the moon and Mars.

And Sierra Space is involved as well, developing a habitat called the Large Integrated Flexible Environment (LIFE).

Similarly, Lockheed Martin is testing inflatable structure concepts that offer advantages over all-metal counterparts.

Each group is eyeing the promising potential for expandable technology. And each company has its own proprietary "secret sauce" embedded in their products.

Related: NASA's moon-orbiting space station will be claustrophobic, architect says

Megastructures

"The future of space is limited by space," explained Maxim de Jong, co-founder of Max Space, based in Jacksonville, Florida with design offices in Vancouver, Canada.

No stranger to expandable space structures, de Jong designed the pressure restraining hulls of Bigelow's Genesis 1 and 2 — the first spacecraft on orbit to successfully incorporate large-volume, high-stress inflatable architecture.

"We are gearing up to fly our maiden mission in 2026," de Jong told Space.com. Within that process, the group has recently performed successful deployment tests of a new space debris shield design. "That is a real progress discriminator, given how challenging, in terms of design, time and cost, debris shield development is."

The Max Space goal is to have a family of scalable habitats in space, ranging from 20 cubic meters (700 cubic feet) to 100 cubic meters (3,500 cubic feet) to 1,000 cubic meters (35,000 cubic feet) thru 2030. There's the potential to scale up to 10,000-cubic-meter (350,000 cubic feet) "megastructures" that could be launched into space on a single flight, using SpaceX's Starship megarocket or Blue Origin's New Glenn, "once they're online," the Max Space website states.

Greater volume and less mass

Lockheed Martin experts explain that inflatable structures offer greater volume for less mass. That translates into larger habitable volumes capable of being rocketed into space, tucked inside reasonably sized payload fairings.

Recently, a pathfinder unit built for airlock applications underwent pressurization and depressurization checks. The airlock design was put through multiple cycles to assess "creep" factors of its Vectran material makeup.

Lockheed Martin, in partnership with NASA's Marshall Space Flight Center in Alabama, initiated a 100-hour "creep" test in which the softgoods unit is pressurized to a percentage of its ultimate burst pressure of 285 pound per square inch (PSI) and held at this pressure until a burst failure occurs as a result of creep.

Creep is permanent material deformation.

"The targeted time-to-failure for this test was around 100 hours," said Uy Duong, habitation chief engineer at Lockheed Martin. "This test has already made it past the 1,500-hour mark without failure, and we will continue the test until burst or mid-December if no burst event occurs between now and then."

Duong and company colleagues are eyeing large, inflatable habitats for use at the moon and Mars, as well as in low-Earth orbit.

Lots of room

Shawn Buckley is vice president of Space Destinations and In-Space Infrastructure at Sierra Space in Louisville, Colorado. Formerly, he was a key BEAM architect at Bigelow Aerospace.

Now, at Sierra Space, Buckley and his team are busily at work on the LIFE habitat, blueprinting a product evolution line that could lead to a module offering 5,000 cubic meters (175,000 cubic feet) of volume by expanding to over 70 feet (22 m) in length and 62 feet (19 m) in diameter.

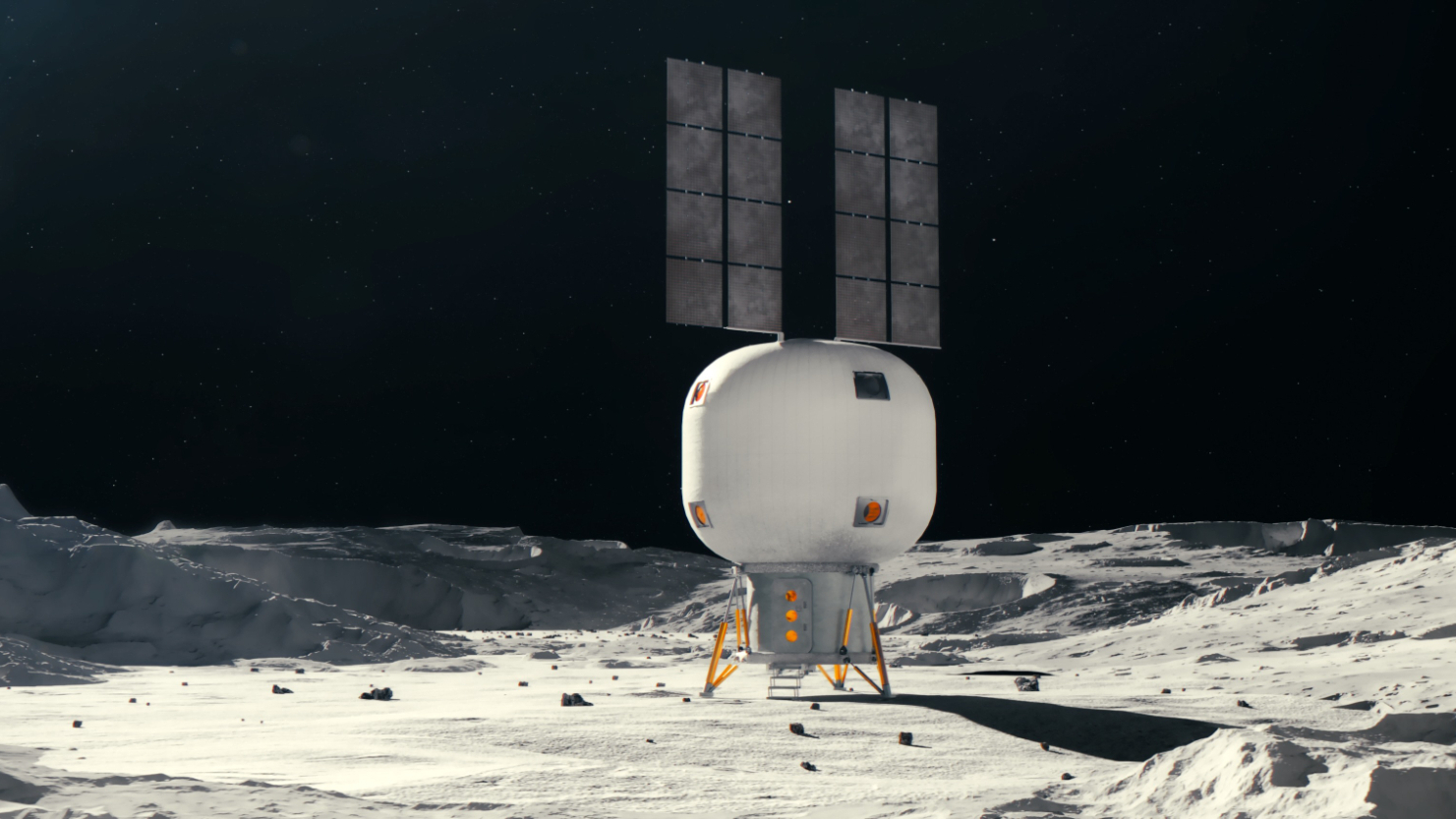

The first product in the Sierra Space roadmap is a large, expandable three-story structure that is 27 feet (over 8 m) in diameter. It can be placed into Earth orbit by a conventional rocket outfitted to house four astronauts, with "spacious" room for science experiments, workout gear, a medical center and a special greenhouse that grows food for explorers on long-duration missions.

"In a little over 2.5 years, we have been able to build and test seven articles, and now going into our eighth. We're moving at a fast rate," Buckley told Space.com. "The technology is really gaining momentum, and we're moving very quickly."

Buckley said that repeat testing is essential. "That is what gives NASA and our customers the confidence. At the end of the day, the more data that we can get the better informed we are," he said.

Niche purpose

Inflatable habitat structure systems "have a role as one tool in our toolkit for expanding, so to speak, human spaceflight for new markets and missions," said Brent Sherwood, a noted space architect and space domain lead for the American Institute of Aeronautics and Astronautics. His past posts include being a senior vice president of space systems development at Blue Origin.

"Like all tools, they're best used for a niche purpose," Sherwood told Space.com. Expandable structures may find particular use as "connector elements," he added.

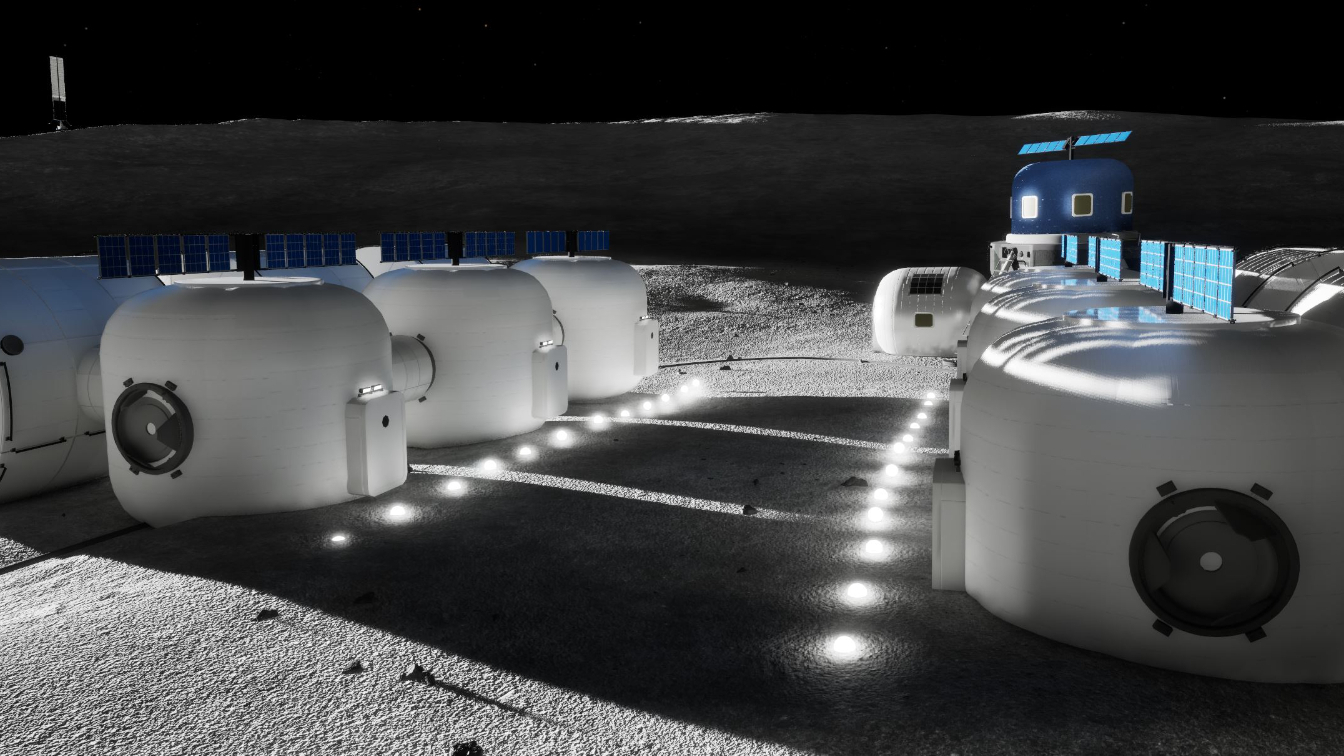

"For example, on the lunar surface, fairly soon we will need physically compliant ways of connecting separate habitat modules," Sherwood said.

"Compliant means accommodating different floor levels — say, from a lander to a pressurized rover — imprecise surface positioning, such as in early base construction, and thermal expansion and contraction due to lunar day/night cycles," Sherwood said.

A little compliance can go a long way to simplifying the overall system architecture, said Sherwood. "So it may be that one of the best uses is comparatively small connector elements rather than the goal of 'making big modules bigger,'" he pointed out.

"Eventually, we will have to learn how to fabricate super-big pressure vessels in space, but we have a lot of market growth and validation to do between now and then," Sherwood concluded.

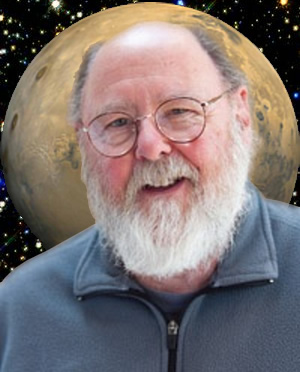

Leonard David is an award-winning space journalist who has been reporting on space activities for more than 50 years. Currently writing as Space.com's Space Insider Columnist among his other projects, Leonard has authored numerous books on space exploration, Mars missions and more, with his latest being "Moon Rush: The New Space Race" published in 2019 by National Geographic. He also wrote "Mars: Our Future on the Red Planet" released in 2016 by National Geographic. Leonard has served as a correspondent for SpaceNews, Scientific American and Aerospace America for the AIAA. He has received many awards, including the first Ordway Award for Sustained Excellence in Spaceflight History in 2015 at the AAS Wernher von Braun Memorial Symposium. You can find out Leonard's latest project at his website and on Twitter.