James Webb Space Telescope: The engineering behind a 'first light machine' that is not allowed to fail

The most complex and expensive space observatory ever built, has pushed engineers and technologies to their limits.

Randy Kimble will never forget the days in August 2017 when Hurricane Harvey battered Texas. As a project scientist for integration, test and commissioning of the James Webb Space Telescope (JWST), he had no option to hide at home. The giant telescope, at that time already 10 years behind schedule and considerably over budget, was right in the middle of one of its 100-day space simulating test campaigns at NASA's Johnson Space Center in Houston.

"The main gate was under several feet of water and the rest of the center was shut down," Kimble told Space.com. "But there was still one route from a hotel strip in that area and you could get in through the back gate at Johnson. Just by a matter of days, we didn't run out of liquid nitrogen to keep the cooling system going. It was very tense."

Kimble has worked on JWST since 2009 after spending two decades developing instruments for JWST's predecessor, the Hubble Space Telescope. Still, he said, the tests of JWST, carried out inside the 40-foot diameter Chamber A (built in the 1960s to test equipment for the moon-bound Apollo missions), were a career highlight. They involved lowering the telescope's temperature to the minus 390 degrees Fahrenheit (minus 217 degrees Celsius) in which it will operate, and in a vacuum similar to that of space.

Live updates: NASA's James Webb Space Telescope launch

Related: How the James Webb Space Telescope works in pictures

"The cryo-vacuum tests for Webb were long and gruelling," Kimble said. "It would take weeks just to cool everything down safely and then warm up again safely at the end of the test. And in the middle, when you are cold and stable, that's when you do your detailed testing."

Over a six-year period, multiple test campaigns were conducted with teams working on site 24/7, including weekends and holidays, Kimble said. The spacecraft's four scientific instruments were also tested separately, multiple times, and so was virtually every part of the telescope, the most complex, daring and expensive space observatory ever built.

Some 30 years in the making and with an eventual price tag of $10 billion, the James Webb Space Telescope is simply not allowed to go wrong. The problem is that in the space business, it is rather easy to go wrong.

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Lessons from Hubble

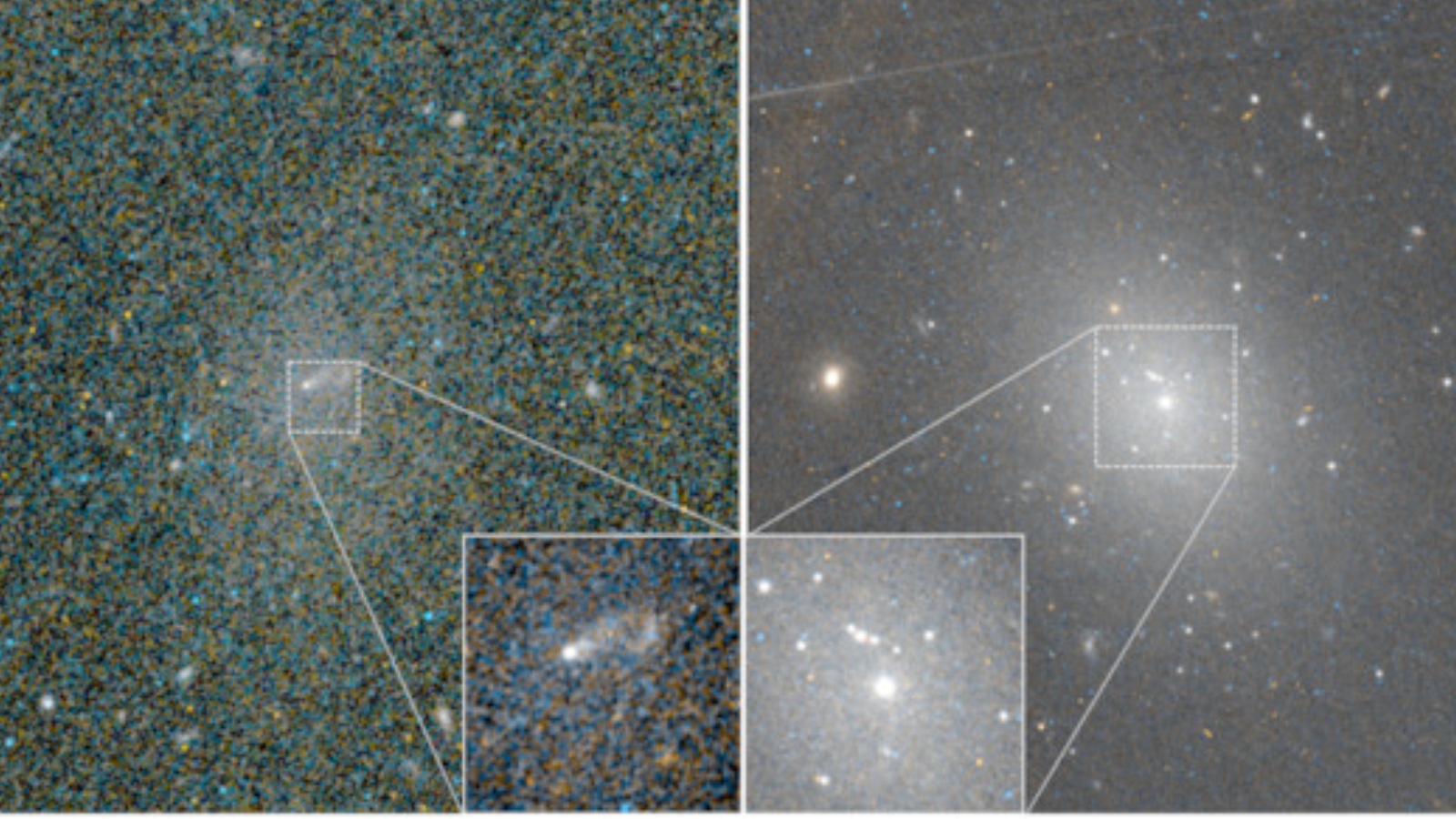

When the Hubble Space Telescope launched in 1990, it soon became obvious something was amiss. The images it sent to Earth were disappointing, blurry, nowhere near to what scientists had expected. The problem was traced to the telescope's great mirror, which was improperly polished during manufacturing. A rescue mission involving a team of astronauts was sent to fix the problem. Hubble received 'glasses' to correct its short-sightedness and turned into the astronomical powerhouse that has since generated thousands of iconic and scientifically priceless images.

With the James Webb Space Telescope, rescue missions are impossible and therefore no failures are allowed.

"James Webb Space Telescope is a prototype and with prototypes, you can always have something that goes wrong," Mark McCaughrean, senior advisor for science and exploration at the European Space Agency (ESA) and interdisciplinary scientist at the JWST science working group, told Space.com. "That's why JWST is so expensive. Because we've spent two decades building and testing every single piece a million ways to do everything to make sure it doesn't have problems."

But why does Webb have to be so complex? Wouldn't a simpler mission work just as well? And why cannot it be serviced by astronauts?

The fact is that serviceability was never an option for Webb. The science it is meant to deliver, the depths of space it is intended to glimpse, simply cannot be accomplished with a spacecraft that astronauts can visit (at least not with currently available spaceships).

The first light machine

The James Webb Space Telescope, sometimes fondly referred to by astronomers as the 'first light machine,' was built to see the first stars and galaxies that emerged from dust and gas of the early universe, only a few millions of years after the Big Bang.

Because these stars and galaxies are so far away, the visible light they emitted when the universe was only a few hundred millions of years old has shifted into the near infrared and infrared part of the electromagnetic spectrum. This strange effect, known as the red shift in astronomical jargon, is a result of the expansion of the universe and the ensuing Doppler effect. That's the same effect that distorts the frequency of a siren of a passing ambulance car.

Infrared radiation is essentially heat, and can be detected with special sensors that are different from those detecting visible light. Since the stars and galaxies that JWST was designed to study are so far away, the incoming signals are also extremely faint. The scientists and engineers behind JWST needed to tackle a range of technical obstacles to make this hoped-for detection possible.

Far from Earth

The Hubble Space Telescope, although originally designed to detect only the visible light of the universe (that in wavelengths that the human eye can process), was in 1997 equipped with then cutting-edge infrared detectors during the second servicing mission; these sensors were later upgraded when new technology became available. But still, infrared astronomy was an obvious afterthought for Hubble, and the telescope clearly wasn't optimized to feel the warmth of the most distant universe.

Hubble orbits Earth at the altitude of 340 miles (545 kilometers). On top of being regularly blasted by direct sunlight, Hubble also absorbs Earth's heat. As a result, its infrared detectors are quite dazzled by the telescope's own warmth and it simply cannot see those faint and distant galaxies.

"If you want a really sensitive infrared telescope, it needs to be really cold," McCaughrean said. "And to get really cold, you need to get away from Earth."

And the James Webb Space Telescope will be far away from Earth indeed, about 1 million miles (1.5 million km) away. That's more than four times farther than the moon. The telescope will orbit the sun, while simultaneously making small circles around the so-called Lagrange point 2 (L2) — a point on the sun-Earth axis constantly hidden from the sun by the planet. At L2, the gravitational pulls of the sun and of Earth keep the spacecraft aligned with the two big bodies.

But even that wouldn't make Webb cold enough to accomplish its mission.

SPF 1 million

The largest piece of the spacecraft — and one without which the mission would be impossible — is its tennis court-sized deployable sunshield made of five layers of an aluminum-coated space blanket material called kapton.

The sunshield will unfurl in space before the telescope reaches its destination in one of the most nerve-wrecking parts of the spacecraft's post-launch deployment sequence.

"The sunshield is by far the most mission-critical thing," said McCaughrean. "If it doesn't fully deploy, the telescope doesn't work. We have obviously folded and unfolded it many times on the ground, but nothing like this has ever been flown in space before, and the lack of gravity simply changes things."

The sunshield is James Webb Space Telescope's main cooling mechanism. Nestled behind it, the mirrors and the four never-before-flown instruments will remain far below freezing at 390 degrees Fahrenheit (minus 217 degrees Celsius). The sun-facing side, on the other hand, will be incredibly hot — up to 230 degrees F (128 degrees C).

"The sunshield is like sunscreen with an SPF of at least a million in terms of how much it attenuates the solar energy," said Kimble, the testing and integration project scientist who rode out Hurricane Harvey with JWST. "That allows us to passively cool down cold enough that for most of the wavelengths, the observations are not limited at all by the glow of the telescope."

The sunshield is not a simple parasol; a lot of clever engineering went into its design. The five layers of the ultralight kapton material are precisely spaced so that the heat absorbed by each layer is perfectly radiated away from the spacecraft through the gaps. While superthin and ultralight, the material is also incredibly sturdy, enough to survive bombardment by meteorites.

Giant mirror

To do what it has been designed to do, the James Webb Space Telescope really couldn't be small. The Hubble Space Telescope, with its mirror 7.8 feet (2.4 meters) in diameter, couldn't detect those distant early galaxies even if it were as cold as Webb.

"If you want to see those distant, faint galaxies, then you need to gather more light," Kimble said. "And so the simple fact that Webb's mirror collects six to seven times more photons in a given amount of time [than Hubble], gives you a significant advantage."

The ability of a telescope to collect light increases with the square of the size of its mirror, explained McCaughrean. With its 21-foot (6.5 m) mirror, Webb will not only be able to take sharper, deeper images of the universe than those that made Hubble famous, it will also do so in a fraction of the time required by Hubble.

"Some of the deep field work that Hubble has done, they would look in a particular field for a couple of weeks," Kimble said. "Webb can reach that kind of sensitivity limit in seven or eight hours."

Too big for space?

But here comes another challenge. How do you lift something the size of a tennis court with a 21-foot mirror into space?

The Hubble Space Telescope, which measures 44 feet long (13.2 m) and at most 14 feet (4.2 m) across, fitted quite snugly into the 60-foot long (18.3 m) and 15-foot wide (4.6 m) payload bay of the space shuttle Discovery, from which the telescope was deployed in 1990.

But the widest rocket fairing available when Webb was designed was Europe's Ariane 5 rocket, and the telescope's mirror is more than 3 feet (1 m) too wide to fit. So for Webb, getting to space requires folding and unfolding. The mirror and the sunshield, as well as the usual solar arrays and antennas, must all be neatly stowed for the telescope's launch.

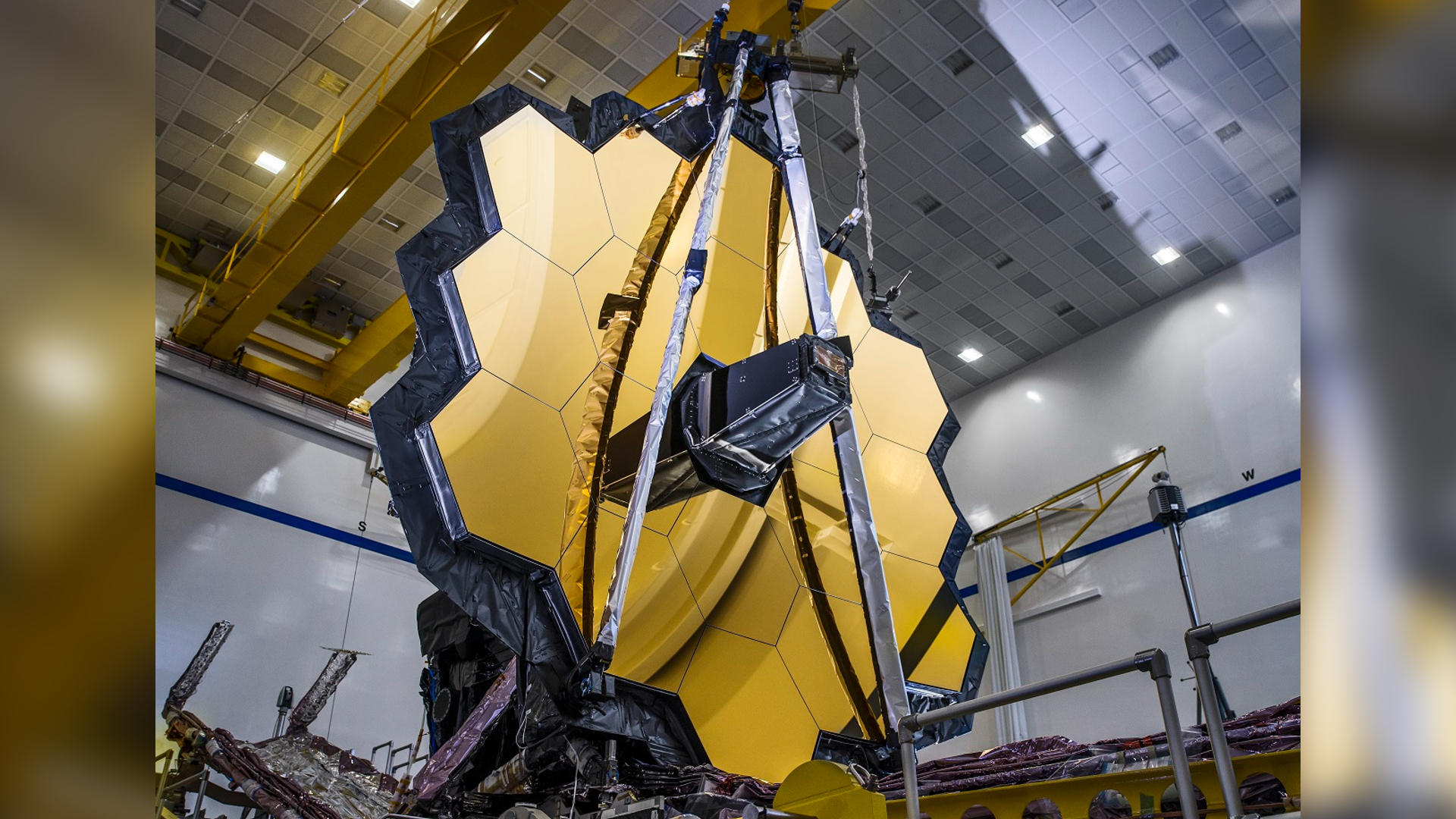

Golden lightweight origami

The mirror, made of 18 hexagonal segments, each 4.3 feet (1.32 m) across, collapses like an origami for the launch. Once in space, these elements unfold, locking together. The jigsaw puzzle is so finely tuned that once the mirror is fully aligned, the seams between the individual segments will be perfectly smooth.

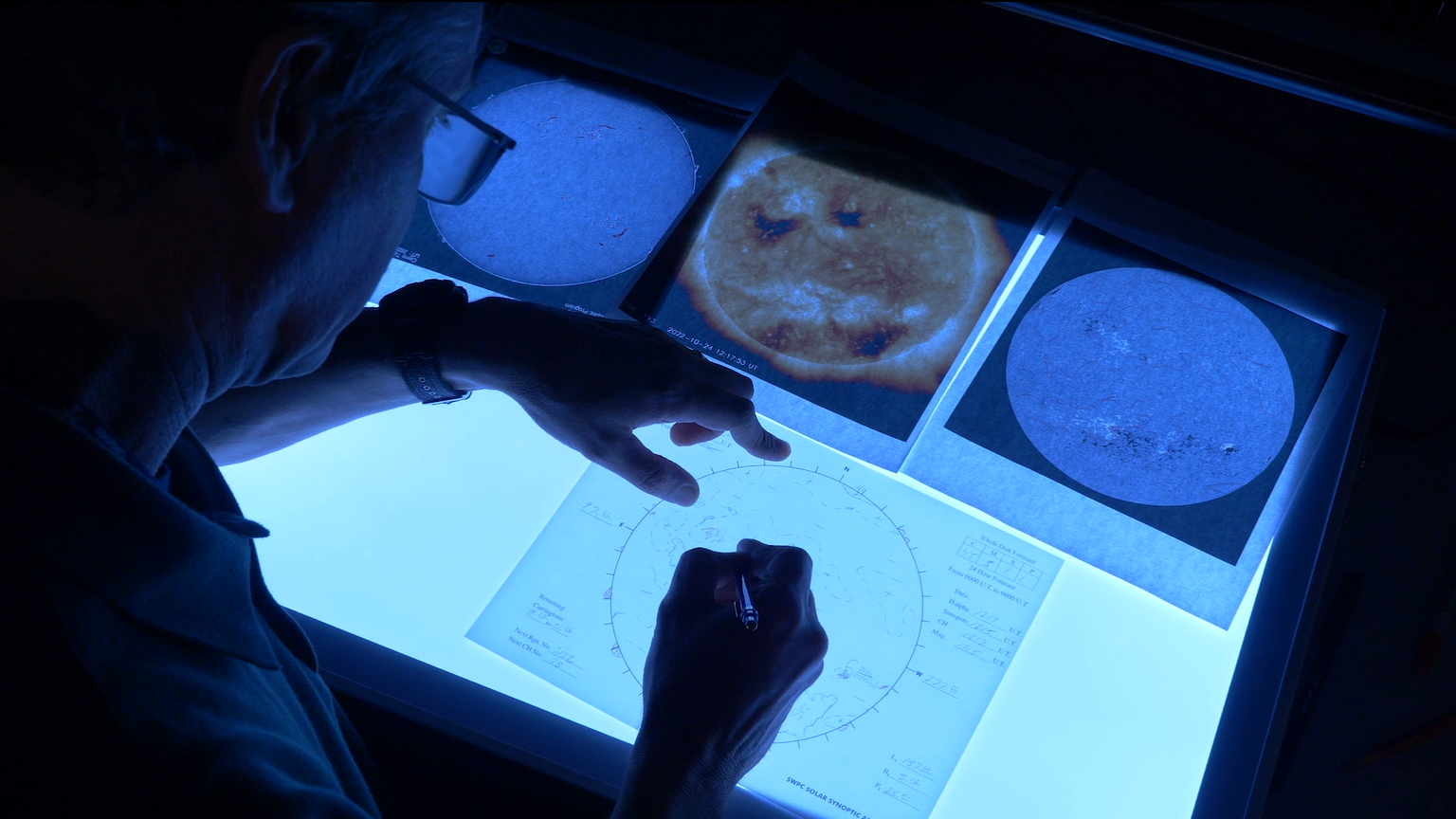

Aligning the mirror once in space will be an intricate endeavour of several months, relying on one of the cameras aboard the spacecraft, the NIRCam instrument.

"Aligning those mirror segments to make a smooth, continuous mirror shape out of them is going to be fascinating," said Kimble. "At the beginning, we will produce 18 separate images with NIRCam; at the end, we will have a single beautiful image."

NIRCam, McCaughrean said, just like many other components of the telescope, is simply not allowed to fail.

"If NIRCam failed, you won't be able to line up the telescope," said McCaughrean. "That's why there is lots of redundancy in it. It has got two completely separate camera systems inside, so if one fails, you have the other one."

At the backs of the 18 hexagonal mirror segments are small motors that delicately press onto the plates, shifting and bending them with extreme precision until they create one giant, perfectly smooth mirror.

"That means movement at the level of nanometers," said McCaughrean. There are 25.4 million nanometers in one inch. "It's incredibly complicated. And that's why it takes so long for us to actually commission the telescope. We launch it in late December, but the first images won't come until the summer of 2022 because it takes that long to line everything up."

The mirror also needed to be extremely lightweight. Had the engineers simply scaled up the 8-foot glass mirror of the Hubble Space Telescope to build the 21-foot mirror of Webb, the telescope would be too heavy for any existing rocket to lift.

As it is, Webb's mirror is about an order of magnitude lighter per unit area compared to Hubble's mirror. Each of the 18 hexagonal segments, made of ultralight metal beryllium, weigh only 46 pounds (20 kilograms). The entire spacecraft, despite its enormous size, weighs only 6.5 metric tonnes compared to the 11.1 metric tonnes of the smaller Hubble.

The surface of the mirror is plated with gold, giving it the signature yellow tint. "The golden color was chosen because it's the best for reflecting infrared radiation, much better than white or silver," says McCaughrean.

The light reflected by the giant mirror is then concentrated onto the 30-inch (74 centimeter) secondary mirror that sits opposite the large mirror attached to a foldable tripod that must also deploy in space. From there, the light enters through an opening at the center of the large mirror into the telescope, where a tertiary mirror sends it to the detectors.

Extended thrill

The James Webb Space Telescope launch is currently scheduled for Friday (Dec. 24). Launch day will be a big moment for the thousands of engineers and scientists who have been involved in the mission since its conception in the early 1990s.

But even after launch, the telescope, which has stretched so many people and so many technologies to their limits, will not allow them to rest. The launch will be the beginning of what Kimble described as "extended thrill," a six-month period of gradual deployments, cooling down, switching on, aligning and testing.

"The first weeks, during our journey to L2, that's when we will see the major deployments," said Kimble. "The sunshield, the mirror, the secondary mirror's support tripod, the solar wings. The telescope will build itself like an origami."

In a press conference held on Nov. 2, Mike Menzel, Webb lead mission systems engineer at NASA Goddard Space Flight Center, said that 144 release mechanisms must work as intended for the deployment to succeed.

"There are 344 single-point-of-failure items on average," Menzel said in that press conference. "Approximately 80% of those are associated with the deployment."

Assuming all its deployments work as intended, Webb will be perched at L2 approximately one month after launch, hidden behind its giant sunshield. Then the telescope will perform the procedure Kimble tested in Houston during Hurricane Harvey — slowly cooling down to its operational temperature while testing its instruments and aligning its mirrors.

"We can do some rougher alignments on the way down as the system is cooling," said Kimble. "At that stage, the structures will still be moving a little because of the cooling and shrinking, so the final tweaking can only be done after we reach temperature stability," 100 to 120 days into the mission.

For Kimble, these months will represent a peak of his career, ensuring that he is "going out with a bang," he said. After more than four decades working on the most cutting-edge space telescopes, the scientist said he is ready to hand over the magnificent first light machine to others after the end of its nerve-wracking commissioning period.

"It's going to be very, very intense," he said.

Follow Tereza Pultarova on Twitter @TerezaPultarova. Follow us on Twitter @Spacedotcom and on Facebook.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Tereza is a London-based science and technology journalist, aspiring fiction writer and amateur gymnast. Originally from Prague, the Czech Republic, she spent the first seven years of her career working as a reporter, script-writer and presenter for various TV programmes of the Czech Public Service Television. She later took a career break to pursue further education and added a Master's in Science from the International Space University, France, to her Bachelor's in Journalism and Master's in Cultural Anthropology from Prague's Charles University. She worked as a reporter at the Engineering and Technology magazine, freelanced for a range of publications including Live Science, Space.com, Professional Engineering, Via Satellite and Space News and served as a maternity cover science editor at the European Space Agency.