Rocket Lab is developing another booster.

The California-based company, which routinely gives small satellites dedicated rides to orbit with its Electron rocket, announced on Monday (March 1) that it's going to build a new, bigger launcher called Neutron. That same day, Rocket Lab also revealed that it will become publicly traded after a planned merger with Vector Acquisition Corporation, a move that will help fund the Neutron work.

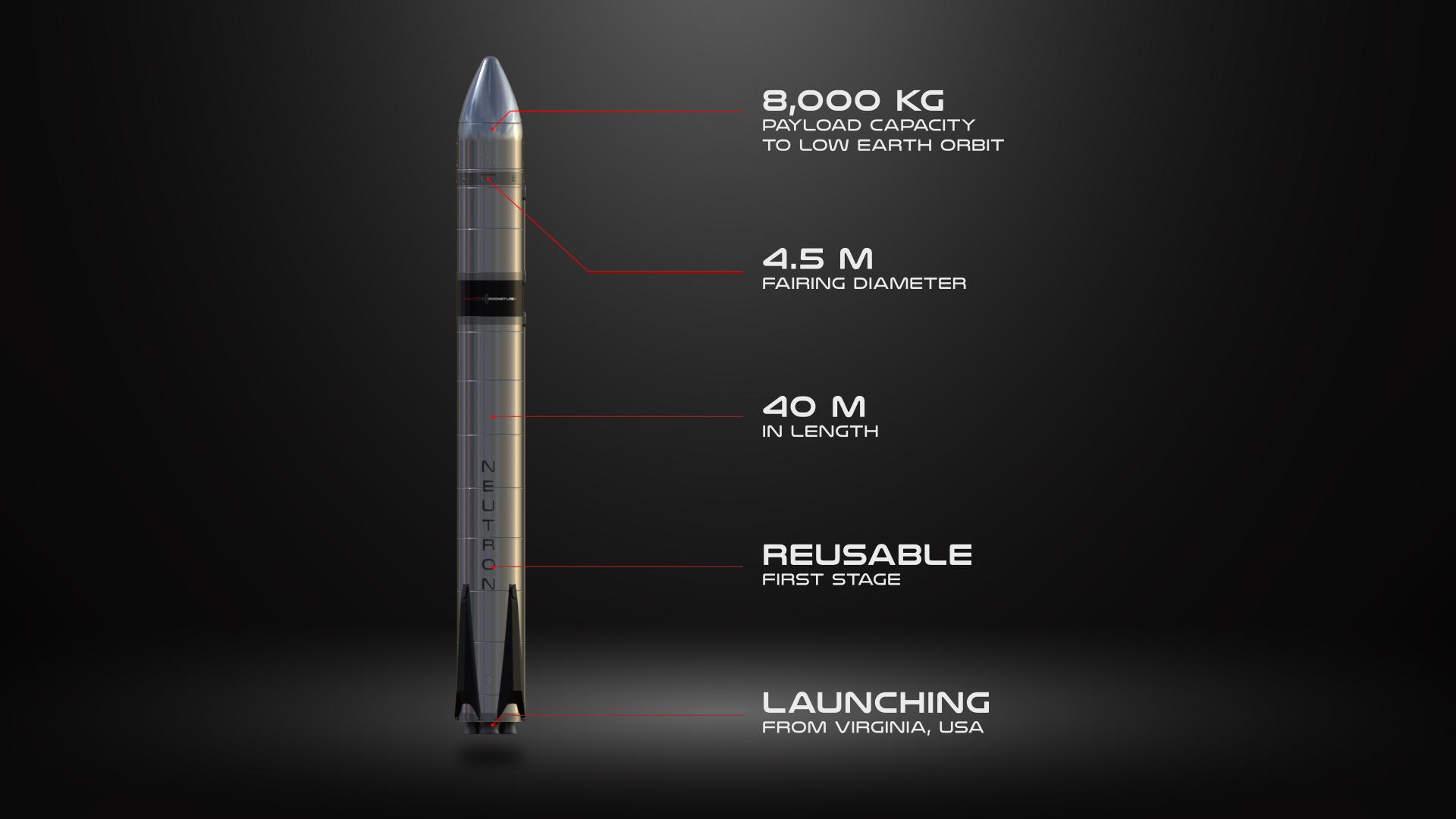

The 130-foot-tall (40 meters) Neutron, which is expected to debut in 2024, will be able to launch up to 8 metric tons (17,600 lbs. or 8,000 kilograms) to low Earth orbit. Its first stage will be reusable, landing on a ship at sea shortly after launch the way first stages of SpaceX Falcon 9 and Falcon Heavy rockets do on some missions.

Rocket Lab had long said it would be content launching relatively small, expendable vehicles. Company founder and CEO Peter Beck even vowed to eat his hat if Rocket Lab ever went reusable. With the Neutron news and Rocket Lab's progress on making Electron's first stage reusable, Beck felt it was time to honor his promise: He actually did eat his hat — well, shreds of it anyway, as Rocket Lab's Neutron announcement video shows.

Neutron is tailored primarily to help build satellite megaconstellations, but Rocket Lab sees other potential uses for it as well. The medium-lift rocket could eventually launch missions to the moon, Mars and Venus, for example, and it will have all the safety features necessary for crewed spaceflight.

Space.com caught up with Beck on Monday to talk about Neutron, the company's plans going forward and how that hat tasted. (The interview has been edited for length.)

In photos: Rocket Lab and its Electron booster

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Space.com: Why did you guys decide to develop a new, medium-lift rocket at this point? Why expand beyond Electron?

Peter Beck: That's a very good question. So firstly, I guess, Electron has enabled us to fly a whole lot of customers and work with a whole lot of customers. And we have really good industry insight [into] where everybody's pain points are and where everybody's going. And then also, with our satellite component business, we are a supplier of components into some major constellations, so we've got really strong relationships there as well. We kind of stood back and listened to those folks and then assessed the needs of today.

Take, for example, a [planned] Telesat constellation, the Lightspeed constellation — 220 satellites, 700 kilograms per satellite, 22 orbital planes, 11 satellites per train. Guess what? That's an 8-ton rocket to populate that plane. And 22 of those planes. That's an obvious need of today. And then you look at what's happening within the industry, and all the planned government and civil constellations — they all pencil out around about that. It's pretty obvious that this is where it all [is going].

And if you look at the majority of launch in history, it pencils out to around about 4.5 tons [per liftoff]. And if you look at the most successful launch vehicle in history, the Soyuz or R-7, it's an 8-ton-lift launch vehicle.

Now, if you look at the rationale for why you would build a much larger vehicle — if you want to lift a school bus-sized satellite into geostationary orbit, that's great. But that's not where the market's going, and that's not the need of today. There is a strategic need for a country to have that lift capability. But where it all penciled out for us is that an 8-ton class is really the sweet spot. And I think we're kind of OK at identifying these market niches. I mean, we did it with Electron, and we've yet to be proven wrong on that one.

Now I'm going to go on to the question about human spaceflight, because I'm sure that's one you want clarity on. So, here's the rub: If you're going to build an 8-ton class launch vehicle, and you're going to go to all the trouble to do it, then you may as well make it human-certifiable from day one. Because the last thing you want to do is [try to make it human-certifiable] in a year's time.

And I'll tell you what: I have learned the hard way, hence the reason that I ate my hat — you should never, ever cap your ambitions. I'm not doing that again. So I'm preparing to make sure that, if I wake up one morning and say, "Right, now we're going to do some human spaceflight," then I don't eat another hat.

There's a lot of things you have to do — safety factors, triple redundancy and all that kind of stuff that would just be horrific to go back and do. So, we simply did a hard requirement from the outset: "Right. Let's make this human certifiable."

Related: The history of rockets

Space.com: So you don't have any immediate plans to start launching people? You just don't want to be in a situation where, if you have the chance to launch astronauts, you have to go back and kind of re-engineer the rocket and do all of the human safety stuff.

Peter Beck: Exactly. And I'm never gonna say that I'm never gonna do something again. I'm keeping all options open from this point.

Space.com: Did you actually swallow that piece of blended hat, or did you spit it out? And did you not put any hot sauce on it or anything? That would have made it go down a little easier, I think.

Peter Beck: Yeah, I did [swallow it]. It probably wasn't as well-thought-through as it could have been. There was talk of cake hats, but no: if you're going to commit to something in this world, you commit to it.

Space.com: So how does Neutron compare to Electron? Do you need to do anything all that differently, or is it just a matter of scaling things up?

Peter Beck: There are areas we're innovating and areas we're not. The key to this vehicle is going to be reusability. So, that's the area we're spending the most amount of time and innovation on. We're not trying to extract the last second of ISP [specific impulse] out of an engine; really, our focus here is on making the most reusable vehicle possible. So, it's not a Rutherford engine [as in Electron]. It's a new engine program for sure for us. But you know, we've built a bunch of engines now, and we're pretty happy with that.

And we have re-entered and recovered an Electron. So, we actually know what it takes to recover a vehicle. And we know the thermal environments; we know what to expect with atmospheric re-entry. That's really, really helpful in informing us what material selections and configurations we're aiming for with Neutron.

There's a lot of scars and bruises from developing Electron, so it's almost luxurious that we have the ability now to roll that into a clean-sheet design and move forward. But there's a bunch of stuff that's common as well. So, all the avionics and electronics are just direct swaps. There is a lot of commonality and direct scaling and design that falls directly across, but there are some new areas.

Related: Rocket Lab on road to reusability after successful booster recovery

Space.com: Do you already have a target price point for Neutron? Are you trying to get well below SpaceX's $62 million price for a Falcon 9 launch, or is that something that you haven't decided on yet?

Peter Beck: I mean, we wouldn't have embarked on a project like this if we didn't feel like we could be highly competitive in the market. And what I will say is that it's been really helpful for us to begin with a vehicle that had a sticker price of $7.5 million [Electron] because a tremendous amount of things are just completely agnostic to the size of the vehicle, like flight safety, licensing, payload separation dynamics and thermal analysis of the spacecraft environment. All of these things, it doesn't matter what size the vehicle is, you have to do.

And, you know, if you don't have a $65 or $68 million vehicle to amortize those things in, you can't be lazy. So we've had to be hyper, hyper efficient with everything we've done. And not just things like licensing and analysis, but on the production floor as well — just really, really lean. So it's kind of like we're forced to be fast and lean, and then now we step into a much larger vehicle. It's going to be very good.

Space.com: You have a lot of interest in going to the moon and in going to other planets, especially Venus. Where do you see Neutron fitting into a broader exploration envelope for you guys? Do you foresee Neutron missions to Venus, Neutron missions to Mars? Is that one of the big reasons why you're doing this?

Peter Beck: Yeah. It certainly opens up the envelope to really exciting things. Imagine putting like 30 Photons onboard and sending them all to Venus — that would be incredible.

Our whole view on interplanetary science is that, when we're in the laboratory on Earth, we don't do one experiment every 10 years. We do 100 experiments and iterate and learn quickly. The Photon interplanetary probe, coupled with a Neutron, is a formidable science tool for sure. So, that would be awesome.

Space.com: When you say you want Neutron to be very reusable — do you have a target in terms of how many times you want each first stage to fly, or is that something that's going to shake out as the design work continues?

Peter Beck: I think we'll be designing it as best we can to be like aircraft operations. Obviously that's not always possible, but that's at least a design measure that we're going in with: How do we do a minimum amount of service in between flights and get the minimum amount of turnaround time? And hopefully soon we'll release some more information about what we're doing. I think people will be surprised.

Space.com: You've got two different recovery strategies for your two rockets — the helicopter strategy for Electron and now landing on a platform at sea with Neutron. Is it a challenge to have two different rocket programs with two different landing strategies?

Peter Beck: Not really. I mean, Electron is a very mature product now. The recovery element is still under work, but from my perspective, we've done the hardest thing, and that's get one back in good condition. So, from here on in it's just logistics and tweaking. I don't see having two different kinds of recovery techniques as really too much of a hindrance.

Space.com: So what do you see as the biggest challenge going forward with the new vehicle?

Peter Beck: Well, it kind of drives to the reason why we entered this transaction [with Vector Acquisition Corporation], because I would have said reliable access to capital was one of them. I think this is the thing that makes me so excited about this transaction — now we have access to capital, and a large amount of capital, to really put the hammer down.

Space.com: Would Neutron not have been possible if you didn't take this step, if it weren't for the acquisition and it weren't for going public?

Peter Beck: The rationale for going public is kind of twofold. One, obviously, we need the capital to execute on Neutron. The other one is, we really had a great acquisition with Sinclair Interplanetary. It's been really good integration in the team; the product's wonderful, and we've been able to scale it and ultimately sell that into megaconstellations. They've been great. But I also think there's a bunch of other things that we want to do that would really benefit the wider Rocket Lab company and fold in some more businesses and talent, and having a public currency is really helpful to do this.

I mean, in full candor, there were some acquisitions that we tried to do last year that we just couldn't. We didn't have a public currency, and others did. So having that public currency certainly helps. Those are fundamentally the two reasons.

Space.com: Neutron is going to launch from your MARS site. [The Mid-Atlantic Regional Spaceport, on Virginia's Wallops Island.] Do you have to build a new launch pad there, or can you use the same pad for Electron and for Neutron?

Peter Beck: That's one of the reasons why we love the Wallops site — this vehicle is directly compatible with Pad 0A. Our intention is to use Pad 0A. There's a lot of investment that the state's made in that pad. It's a relatively low-use pad that we soon hope to utilize. [Note: Pad 0A, which is near Rocket Lab's custom-built Launch Complex-2, now regularly hosts launches of Northop Grumman Cygnus spacecraft on cargo missions to the International Space Station.]

Space.com: You've said that you're currently looking for a manufacturing space in the U.S. for Neutron. When do you foresee making those sorts of decisions, and what's the status of the Neutron work? When do you anticipate actually bending metal?

Peter Beck: I think once the transaction is [officially finished], we can move very, very aggressively on this. So, we'll look to settle down on a manufacturing location pretty quickly. One of the advantages of the design is that we haven't constrained it necessarily to a particular diameter that needs to fit it. We have a wide envelope here we can evaluate from.

Space.com: So, after that hat eating — Would you say never to a heavy-lift rocket? I mean, you've got a small launcher, you're developing a medium lifter now...

Peter Beck: Now you're just trying to put me in a trap! [Laughs.] I'm never going to say never to anything again. I have learned my lesson, and it tasted terrible.

Mike Wall is the author of "Out There" (Grand Central Publishing, 2018; illustrated by Karl Tate), a book about the search for alien life. Follow him on Twitter @michaeldwall. Follow us on Twitter @Spacedotcom or Facebook.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Michael Wall is a Senior Space Writer with Space.com and joined the team in 2010. He primarily covers exoplanets, spaceflight and military space, but has been known to dabble in the space art beat. His book about the search for alien life, "Out There," was published on Nov. 13, 2018. Before becoming a science writer, Michael worked as a herpetologist and wildlife biologist. He has a Ph.D. in evolutionary biology from the University of Sydney, Australia, a bachelor's degree from the University of Arizona, and a graduate certificate in science writing from the University of California, Santa Cruz. To find out what his latest project is, you can follow Michael on Twitter.