How can we build landing and launch pads on the moon?

"These are the first steps to opening up the solar system transportation routes to humanity and resource mining robots."

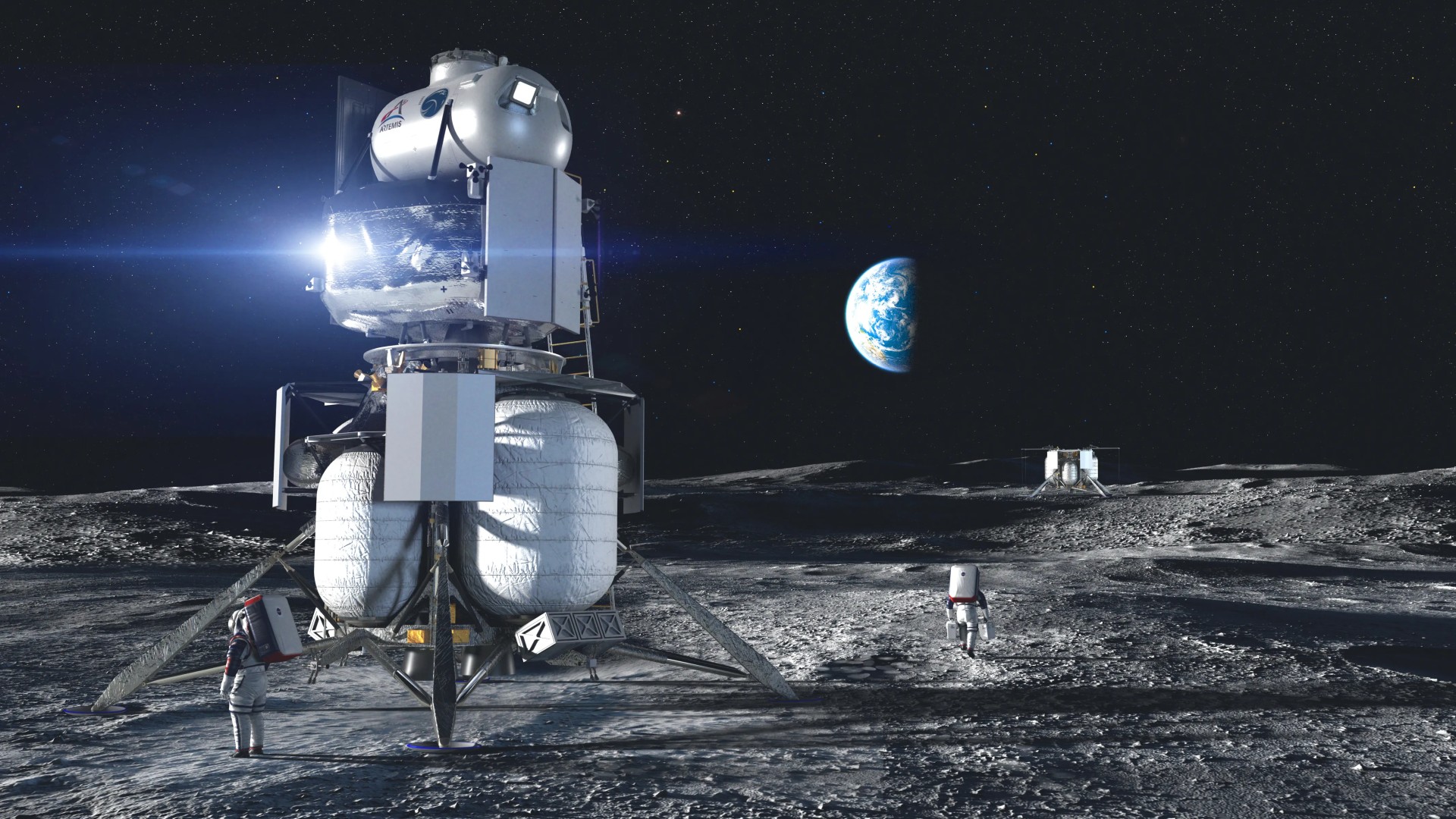

If the future unfolds like some experts forecast, the moon is going to be one bustling spaceport.

Vehicles will routinely blast in and rocket off the lunar surface, part of a supply chain that caters to human encampments, equips science facilities and plops down gear for extraterrestrial mining operations. Early on, it's projected to be a rocket ruckus of kicked-up dust and flying debris. A recent gathering of experts grappled with what we know, what we don't know about how to handle "airport-like" operations on the moon.

The Lunar Surface Innovation Consortium held a moon launch and landing facilities workshop on July 23, 2024. The consortium is administered by the Johns Hopkins Applied Physics Laboratory in Laurel, Maryland. Government, university, and private sector specialists shared ideas on the design, analysis and construction of launch and landing facilities, as well as identify technology gaps in order to establish a sustainable presence on the moon.

Group effort

Major decisions are forthcoming on how to create the infrastructure need if Earth's celestial partner is to become a major thoroughfare and keep up any long-term human habitation there.

"Establishing a human presence on the lunar surface is a group effort," said Ian Jehn, a structural engineer focused on safe and sound infrastructure for the moon. He's also a PhD candidate at the Colorado School of Mines.

"It is likely that before any prominent human presence occurs on the moon, significant mass will need to be launched and delivered to the lunar surface," Jehn told Space.com. "We need professionals from all industry areas to collaborate to produce successful and well-performing lunar infrastructure."

Rocket plumes

Jehn foresees larger launch and landing vehicles on the moon. Those comings and goings mean larger rocket plumes interacting with the lunar landscape.

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

"Mitigating the effects of rocket plume forces is currently a popular study area, as plume gas has the potential to cause cratering of the surface and generate high-speed regolith ejecta that can damage the structure of the vehicle or anything in the surrounding vicinity of the landing zone," he said.

To curb those blast effects, on the discussion topic list is the construction and use of launch and landing pads, or LLPs. Any landing pad surface designer worth his or her "exhausting" design work contribution needs to know what craft class a moon lander falls into.

Reusable, easily repairable

"LLPs will likely need to be reusable or easily repairable," Jehn said, "to ensure the safe and efficient transport of people, mission assets, and material to and from the moon's surface."

LLP systems can leverage some very well-established design and construction practices from the terrestrial civil engineering industry, Jehn explains. Civil and structural engineers have been designing similar systems that are being used right now for SpaceX Falcon and Blue Origin New Shepard landing zones.

Any structural system relies on two components to enable design, Jehn said, and those are anticipated loading conditions and material properties.

Jehn said that for the moon's terrain, a significant effort is underway to develop structural materials. That's work in progress.

But that's also a catch.

Sturdy structures

"The issue is the proprietary nature of rocket plume loading criteria," Jehn points out. However, at present these criteria are being withheld by the NASA's Commercial Lunar Payloads Services (CLPS) and human landing system manufacturers, he said, and they can only be accessed through legally binding non-disclosure agreements.

To that end, Jehn is engaged in work by the American Society of Civil Engineers. That group has initiated the development of "Lunar Infrastructure Engineering, Design, Analysis, and Construction" guidelines.

On the table are such things as what type of construction and materials are required, environmental effects, and dealing with lunar regolith and rocks to assure the fabrication of sturdy structures.

It is typical for rocket plumes from vertical takeoff/vertical landing operations to apply physical pressure and heat flux to the landing and launch interaction surface, Jehn points out. Different rocket nozzles, orientations, and sizes will result in differing pressure and heat concentrations.

"In my opinion, establishing loading conditions is now the priority. You can't design a structural system, like a lunar LLP, without loading criteria," said Jehn. An analogy is trying to design a highway overpass without knowing what type of vehicle is driving over that bridge, he said.

Source of speculation

Given six Apollo missions between 1969-1972 that deposited and safely returned a dozen moonwalkers, why all the fuss and fuming about touching down and departing the moon?

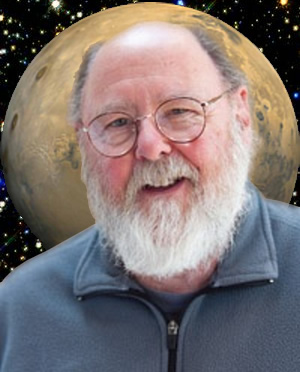

Those Apollo landings created more questions than answers, responds John Connolly, a professor of practice at Texas A&M University's Aerospace Engineering department. His prior NASA career of 35 years included work on the space agency's Artemis human landing system program, where he also worked with commercial lunar lander contractors.

"We know that there is an upper layer of loose lunar regolith that will be blown away by almost any lander propulsion system. But the mechanics of what happens below that — as the regolith layer gets more dense and more cohesive with depth — are still the source of speculation and expenditure of hours of computer simulation time," Connolly tells Space.com.

Changing density

The moon's topside "fluffy" regolith is an overcoat for a "hard packed" denser lunar soil that is less than a few feet below, Connolly reports.

"Knowing that the lunar surface geotechnical properties change rapidly within this first meter complicates our efforts to model the surface because you have to take into account changing density, cohesion, porosity and shear strength," said Connolly. "The engine plume of a lunar lander, after blowing off the loose upper layer of regolith, will continue to interact with the exposed regolith in a number of ways."

It isn't an easy problem to model analytically, Connolly added. There's need to correctly model the engine plume gas flow and then model how the gas will interact with the lunar regolith.

"So you almost need to model each regolith particle individually as it is dislodged from the soil matrix, accelerates in the plume, bumps into other particles, and eventually ends up on a ballistic trajectory," said Connolly. And this would require a huge amount of computational fluid dynamics run time on a supercomputer, he said.

Spray-on solution?

Do we need to prepare a launch/landing pad to keep landers from continuing to scour the lunar regolith and eject it at high velocities at valuable, neighboring surface hardware?

"I believe the answer is yes, but maybe not immediately," Connolly advises. You can initially use the topography of the moon itself as a "berm" to protect surface assets, he said. Just pick a landing site that has a hill or ridge between it and other off-worldly goods and services.

But if you want to continue to land at the same site, you may need to treat it to eliminate the effects of lander rocket plumes, Connolly said.

If that's the case, you could call for shots of "Rhino Snot" — yes, you're reading that correctly. The military dubbed it Rhino Snot — a commercial spray-on polymer used to treat dust-prone areas that increases the soil strength by interconnecting soil particles together.

"The military sprays liquid polymers to quickly stabilize dirt roads and helicopter landing pads, and a lunar-qualified version of this technology could be used for landing pads," said Connolly.

If a longer-term solution is needed, Connolly continued, as in the case of a permanent moon base with regularly arriving and departing landers, a surface treatment such as a deeply sintered regolith pad may be the right answer.

Mission success

"Safe and reliable landings, and eventually launches, on the moon are necessary for mission success," said Rob Mueller, a senior technologist in the granular mechanics and regolith operations lab within NASA's Swamp Works at the Kennedy Space Center in Florida.

Mueller told Space.com that the data output from NASA's Commercial Lunar Payloads Services (CLPS) landers will provide new insights into how rocket engine plumes impact lunar surface materials.

With that knowledge in hand, what's possible in the far term is clear, Mueller said.

"In the future we will see spaceports developing on the lunar surface and other solar system orbital and surface destinations. They will use in-situ derived propellant such as hydrogen and oxygen from water," Mueller said. "These are the first steps to opening up the solar system transportation routes to humanity and resource mining robots."

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Leonard David is an award-winning space journalist who has been reporting on space activities for more than 50 years. Currently writing as Space.com's Space Insider Columnist among his other projects, Leonard has authored numerous books on space exploration, Mars missions and more, with his latest being "Moon Rush: The New Space Race" published in 2019 by National Geographic. He also wrote "Mars: Our Future on the Red Planet" released in 2016 by National Geographic. Leonard has served as a correspondent for SpaceNews, Scientific American and Aerospace America for the AIAA. He has received many awards, including the first Ordway Award for Sustained Excellence in Spaceflight History in 2015 at the AAS Wernher von Braun Memorial Symposium. You can find out Leonard's latest project at his website and on Twitter.

-

fj.torres Pre-built metal modules, raised above the regolith so the lunar vacuum reduces the heating. Designed to deflect the exhaust up and away from the surface and the vehicles. Say, 25ft wide hexagons interlocked.Reply

Vacuum is very useful. And in the lunar gravity, much lower thrust and exhaust is needed. You can do a lot with 100Ton cargo landers if you stop to think moon, not earth. -

Unclear Engineer Useful thinking, but we still would have to provide support for those raised steel plates and whatever spacecraft rest on them and fire rockets onto them. That support must come from the so-far-poorly-understood subsurface of the Moon. So, we really do need to do some on-site surveys of the material properties of the surface as a function of depth. And, we need to realize that those properties are not uniform over the whole lunar surface. So, we need to do those studies where we actually hope to build the pads. So far, no missions have drilled very far into the surface.Reply -

BT2024 I wonder if these autonomous lunar construction machines will be able to work during the weeks of darkness and withstand the day/night temperature extremes. Will there be a repair shop where other autonomous machines fix the broken machines?Reply

Steel plate deflectors sound great, but can you imagine the extra trips to transport that much mass? Maybe a crater the right size and depth would be a better starting place to build a launch/landing pad. -

JPL_ACE You need to take advantage of what ever you can, so I think combining ideas is the way to approach LLP's. Site your base next to 1 or 2 fresh craters, provides a safety berm for free. use Rhino Snot in conjunction with the hot exhaust during landing to fuse the regolith into a hard pad. Later, create a real pad maybe with cut blocks of deep rock.Reply -

Cisventure Astronot Reply

Wouldn't using the vacuum as an insulator between the pad and the ground only make the pad get hotter?fj.torres said:Pre-built metal modules, raised above the regolith so the lunar vacuum reduces the heating. Designed to deflect the exhaust up and away from the surface and the vehicles. Say, 25ft wide hexagons interlocked.

Vacuum is very useful. And in the lunar gravity, much lower thrust and exhaust is needed. You can do a lot with 100Ton cargo landers if you stop to think moon, not earth. -

ChrisA Reply

I don't understand how the vacuum reduces the heating. I think it goes the other way. In a vacuum you only have radiative cooling,.fj.torres said:Pre-built metal modules, raised above the regolith so the lunar vacuum reduces the heating.

Possibly the easy thing might be to just let the loose stuff fly away. Maybe even hover over the landing spot and blast it for some time. I can imagine an unmanned lander whose only cargo is flue for hovering. This would work if the soil got more solid rather quickly.